This article primarily introduces the PREN value of ASTM A182 F51 flanges and their application in corrosive environments. It analyzes the impact of the PREN value on the material’s corrosion resistance and discusses the application prospects of A182 F51 flanges in industries such as petroleum, chemical, and more.

Introduction:

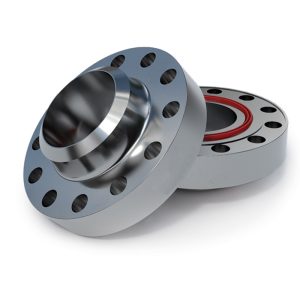

ASTM A182 F51 is a type of duplex stainless steel flange known for its good corrosion resistance, high strength, and excellent welding performance. It has been widely used in industries such as petroleum, chemical, marine engineering, and more. The PREN value (Pitting Resistance Equivalent Number) is an important indicator for measuring the pitting corrosion resistance of stainless steel. This article will discuss the PREN value of A182 F51 flanges and its significance in practical applications.

Section 1: The PREN Value of ASTM A182 F51 Flanges

- Definition of PREN Value

The PREN value is a parameter used to assess the pitting corrosion resistance of stainless steel, calculated by the formula: PREN = %Cr + 3.3(%Mo + %W) + 16(%N). Here, Cr, Mo, W, and N represent the contents of chromium, molybdenum, tungsten, and nitrogen in the stainless steel, respectively. A higher PREN value indicates better pitting corrosion resistance of the material.

- PREN Value of A182 F51 Flanges

According to the ASTM A182 F51 standard, the PREN value of this material should be greater than or equal to 34. This means that A182 F51 flanges have good pitting corrosion resistance in corrosive environments, making them suitable for industries such as petroleum and chemical.

Section 2: The Impact of PREN Value on the Corrosion Resistance of A182 F51 Flanges

- Pitting Corrosion Phenomenon

Pitting corrosion is a common form of localized corrosion in stainless steel in corrosive environments, which seriously affects the normal operation of equipment. Increasing the PREN value of the material is an effective means to reduce the risk of pitting corrosion.

- Corrosion Resistance of A182 F51 Flanges

With a high PREN value, A182 F51 flanges exhibit good pitting corrosion resistance in corrosive environments. In practical applications, A182 F51 flanges can withstand high working pressures and temperatures, making them suitable for harsh corrosive conditions.

Section 3: Application of A182 F51 Flanges in Corrosive Environments

- Petroleum and Chemical Industry

A182 F51 flanges have a wide range of applications in the petroleum and chemical industries, such as in the connection of equipment like towers, heat exchangers, and pipelines. Their good corrosion resistance and mechanical properties ensure the long-term stable operation of the equipment.

- Marine Engineering

In the field of marine engineering, A182 F51 flanges can be used in seawater desalination equipment, offshore platforms, etc. Their corrosion resistance meets the high demands of marine engineering for materials.

The formula for calculating the PREN value is as follows:

PREN = %Cr + 3.3(%Mo + %W) + 16(%N)

In this formula, each symbol represents the following:

- %Cr: The mass percentage of Chromium.

- %Mo: The mass percentage of Molybdenum.

- %W: The mass percentage of Tungsten.

- %N: The mass percentage of Nitrogen.

Here are the steps to calculate the PREN value:

- Determine the content of chromium, molybdenum, tungsten, and nitrogen in the stainless steel, which is usually provided by the material’s standard or chemical composition report.

- Convert the content of each element into a percentage.

- Add the percentage of chromium directly as per the formula.

- Add the percentages of molybdenum and tungsten together, and then multiply by 3.3.

- Multiply the percentage of nitrogen by 16.

- Sum all the calculated results to obtain the final PREN value.

For example, if the chemical composition of a stainless steel is 8% molybdenum, 23% chromium, 0.2% nitrogen, and does not contain tungsten, the calculation for its PREN value would be as follows:

PREN = %Cr + 3.3(%Mo + %W) + 16(%N) = 23 + 3.3(8 + 0) + 16(0.2) = 23 + 3.3(8) + 3.2 = 23 + 26.4 + 3.2 = 52.6

Therefore, the PREN value of this stainless steel is 52.6. The higher this value, the better the material’s resistance to pitting corrosion is generally considered to be. It is important to note that the PREN value is an empirical formula that provides a relative standard for comparison, but in specific application environments, other factors such as temperature, chloride concentration, pH, etc., also need to be considered.

Conclusion:

ASTM A182 F51 flanges have a high PREN value, providing good corrosion resistance. They have been widely used in industries such as petroleum, chemical, and marine engineering. With the continuous development of China’s industry, the market demand for A182 F51 flanges will continue to grow, offering broad application prospects. To ensure the safe operation of equipment, the selection of A182 F51 flanges with a high PREN value is of great significance.