GET IN TOUCH WITH NFI STEEL

Forged 90 Deg Socket Weld Elbow

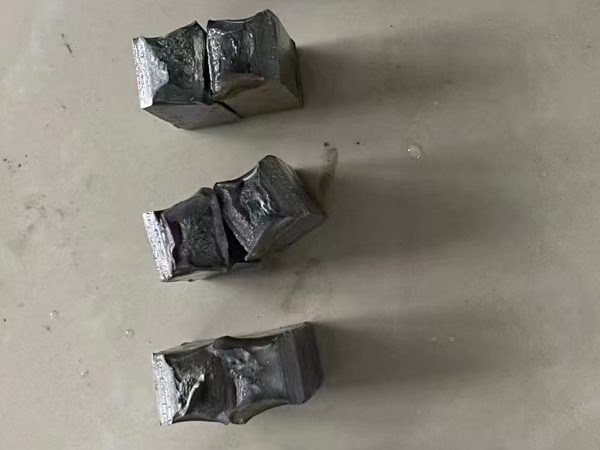

Forged 90 Deg Socket Weld Elbow is a necessary pipe fitting for installation of small-diameter high-pressure pipeline. Because of its high-pressure performance, it is widely used in shipbuilding, petrochemical and other fields.

Carbon steel, low temperature pipeline steel, stainless steel, dual phase steel, nickel base alloy – Forged 90 Deg Socket Weld Elbow

Cangzhou Enfei Pipe Equipment Co., Ltd. is a professional manufacturer ofForged 90 Deg Socket Weld Elbow. The Forged 90 Deg Socket Weld Elbow produced by us is mainly made of metal round bar and hexagonal bar raw materials through stamping production process, and then the finished products are manufactured through heat treatment, grinding and polishing, acid washing and shot blasting.

The manufacturing standards of Forged 90 Deg Socket Weld Elbow produced by us include: ASME / ANSI B16.11, GB /T14383, MSS SP-83, MSS SP-95, MSS SP-97, JB/T11398, SH / T3424, SH/T419, BS3799, GB/T19326, etc. each product of Forged 90 Deg Socket Weld Elbow produced by Cangzhou Enfei Pipe Equipment Co., Ltd. needs to undergo strict testing before it can be delivered to customers with permanent identification, In addition, the raw materials for manufacturing Forged 90 Deg Socket Weld Elbow are the products of the most excellent steel pipe manufacturers in China.

The raw material purchasers include Shanghai Baosteel, Valin steel, Laiwu Steel, Baotou Steel, Taiyuan Steel, Yongxing special steel, Huaxin Lihua and qingtuo group. The material standards forForged 90 Deg Socket Weld Elbow include: ASTM A105, ASTM A182 F11 CL1 F11 Cl2 F11 CL3 F12 CL1 F12 Cl2 F304 F304H F30L F317 F321 F347 F51 F53 F55 F60 ASTM A694 F42 F48 F50 F52 F56 F60 F65 F70, ASTM / ASME SB466 UNS NO.C70600 (Cu / NI-90 / 10), C71500 (Cu / ni-70 / 30), ASTM / ASME SB336, ASME SB564 / 160 / 163 / 472, UNS2200 (nickel200) UNS2201 (nickel201), UNS4400 (MONEL400), UNS8020 (alloy20 / 20 CB3), UNS8825 Inconel (825), UNS6600 (inconel600), UNS6601 (inconel200)601), UNS6625 (Inconel625), UNS10276 (Hastelloy C276), etc.

In the above Forged 90 Deg Socket Weld Elbow production materials, our dual phase steel meets the requirements of A182 F53 / F55 PREN (% Cr + 3.3% Mo + 16% N) ≥ 40, F51 / F60 N = 0.14-0.2% and PREN (% Cr + 3.3% Mo + 16% N) ≥ 34, product pressure 2000lb 3000lb 6000lb 9000lb, and product specification 1/8-4 inch to meet customers’ various choices. After years of customer accumulation and cooperation, Cangzhou Enfei Pipe Equipment Co., Ltd. has sent its products to the United States, Canada, Brazil, Australia, South Korea, Japan, the United Arab Emirates, Qatar, South Africa, France, Germany, the United Kingdom, Italy, the Philippines, Malaysia, Vietnam and other regions.

Industrial Steel Flanges Test Certificates: Cangzhou Enfei Pipe Equipment Co., Ltd. offer its Products with Third Party Inspection also. The Inspection Agency can be nominated by clients or Dynamic Forge & Fittings can be arrange the TPI by World reputed Agencies like Bureau Veritas, ABS, SGS and many other.

Forged 90 Deg Socket Weld Elbow Specification

| Size | 1/8〞(DN6)to 4〞(DN100) | |||||

| Class | 2000LBS,3000LBS,6000LBS, 9000LBS. | |||||

| Types of Socket Weld Fittings | Forged 90 Deg Socket Weld Elbow,Forged 45 Deg Socket Weld Elbow,Forged Socket Weld Equal Tee,Forged Socket Weld Unequal Tee,Forged Socket Weld Equal Cross,Forged Socket Weld Unequal Cross

Forged Socket Weld Full Coupling,Forged Socket Weld Half Coupling,Forged Socket Weld Pipe Cap,Forged Socket Weld Union,Forged Socket Weld Reducer Insert,Forged Socket Weld Boss Forged Socket Weld Branch Outlet,Forged 90 Deg Socket Weld Elbow Outlet,Forged Socket Weld Boss,Forged Socket Weld Lateral Outlet,Forged Butt Weld Branch Outlet,Socket Weld Fittings Forged Socket Weld Pipe Nipples,Forged Socket Weld Pipe Outlet Fittings,Forged Socket Weld Swage Nipples | Pipe Swage |

|||||

| Surface Treatment | Sand Blasting,Cold and Hot Dip Galvanized | |||||

| Manufacturing process | Cutting,Heat treatment,Die Forging/Free Forging,CNC Machining | |||||

| Manufacturing Standards | ASME B16.11,BS 3799,JIS B2316,GB/T14383,SH3410,HG/T21634,MSS SP-79 SP-83 SP-95 | |||||

Material Grades

| Carbon Steel | ASTM/ASNE A105,ASME A350 LF2 LF6 ,A694 F42 F46 F48 F50 F52 F56 F60 F65,C22.8 | |||||

| Stainless Steel | ASTM F304,F304L,F316,F316L | |||||

| Duplex & Super Duplex Steel | ASTM A182-F51,F53,F55,F60,S31803,S22253,S32205,S22053 | |||||

| Alloy Steel | ASTM F5,F9,F11,F22,F91 | |||||

| Copper Alloy Steel | ASTM/ASME SB466 UNS NO.C70600,C71500 | |||||

| Nickel Alloy | ASTM/ASME SB336,ASME SB564/160/163/472,UNS2200(NICKEL200)UNS2201(NICKEL201),UNS4400(MONEL400),UNS8020(ALLOY20/20 CB3)

UNS8825 INCONEL(825),UNS6600(INCONEL600),UNS6601(INCONEL601),UNS6625(INCONEL625),UNS10276(HASTELLOY C276) |

|||||

Forged 90 Deg Socket Weld Elbow Tensile Properties Testing