1、 Characteristics of C276 Hastelloy Prefabricated Pipeline

C276 Hastelloy is a type of cobalt based alloy, which has characteristics such as acid resistance, alkali resistance, high temperature resistance, and corrosion resistance. It is widely used in fields such as chemical engineering, metallurgy, electronics, aviation, etc. C276 Hastelloy prefabricated pipelines have become an important component of chemical pipeline systems due to their excellent performance characteristics. Its main characteristics are as follows:

1. Strong corrosion resistance: C276 Hastelloy is an alloy with extremely strong corrosion resistance, which can withstand the erosion of various corrosive media such as acids, alkalis, and salts, and has excellent corrosion resistance.

2. Good high-temperature stability: C276 Hastelloy alloy can still maintain its stable performance at high temperatures, with a wide temperature range and can adapt to various complex environments.

3. High strength: C276 Hastelloy alloy has high strength and can withstand certain pressure and weight.

4. Good toughness and plasticity: C276 Hastelloy alloy has good toughness and plasticity, making it easy to process and shape.

2、 Manufacturing Process of C276 Hastelloy Prefabricated Pipeline

The manufacturing process of C276 Hastelloy prefabricated pipelines mainly adopts two methods: forging and rolling. The forging method is to heat the raw materials to a certain temperature and place them on a forging machine for processing, in order to produce prefabricated pipes with standardized shapes. The rolling method involves squeezing the raw material into a circular shape, and after multiple pipe expansion processes, it is processed into prefabricated pipes with standardized shapes. The specific steps of the manufacturing process are as follows:

1. Melting raw materials: Add C276 Hastelloy raw materials to the furnace for melting until they become liquid.

2. Casting billet: pour molten liquid alloy into the billet to make it Free cooling and form the billet.

3. Forging or rolling processing: Heat the casting billet to an appropriate temperature, and process it into a prefabricated pipeline of standard shape through forging or rolling.

4. Testing and Inspection: Strictly test and inspect each prefabricated pipeline to ensure the quality of the product.

5. Sizing treatment: For prefabricated pipes that have already been processed and formed, perform sizing treatment to better meet user needs in terms of performance.

6. Packaging and transportation: Package and transport the finished product to ensure that it will not be damaged or deformed.

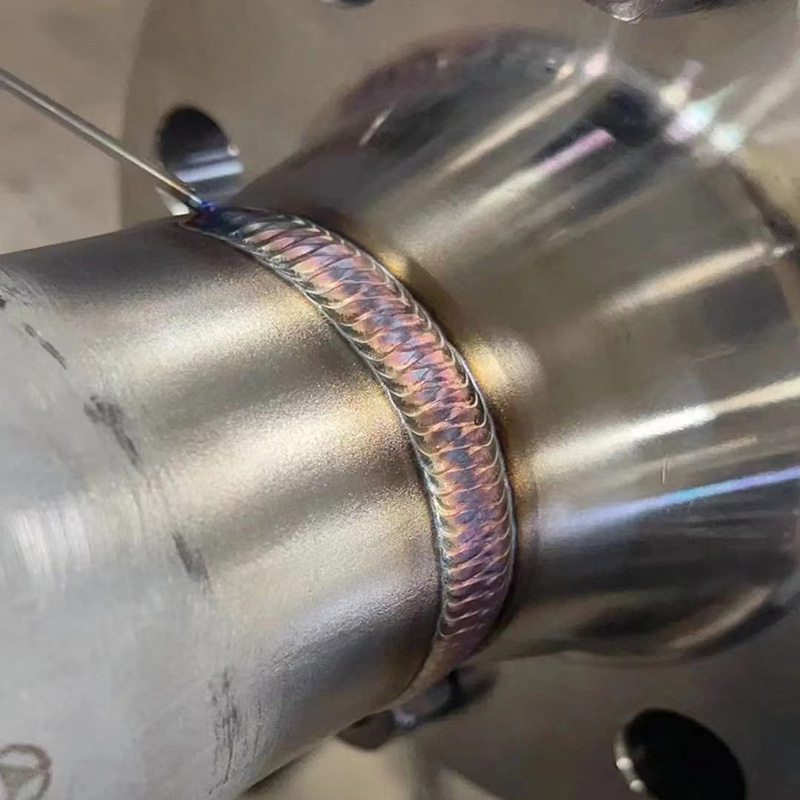

3、 Welding Process of C276 Hastelloy Prefabricated Pipeline

The welding processes of C276 Hastelloy prefabricated pipes mainly include manual arc welding, argon arc welding and plasma welding, of which manual arc welding is suitable for small-scale production and maintenance; Argon arc welding and plasma welding are suitable for large-scale production and high-quality welding of workpieces. The welding process of C276 Hastelloy prefabricated pipeline should pay attention to the following matters:

1. Before welding, the surface should be cleaned to remove dirt and oxides.

2. Select tungsten electrode, suitable welding wire, and protective gas to ensure welding quality.

During the welding process, control the welding parameters and stability of the arc, and use shielding materials to protect the weld seam during welding.

4. After welding, heat treatment can be carried out to ensure the quality and performance of the weld seam.

4、 C276 Hastelloy prefabricated pipeline from Enfei Pipeline Equipment Cangzhou Co., Ltd

Enfei Pipeline Equipment Cangzhou Co., Ltd. is a professional enterprise that produces high-end pressure pipeline systems. Its C276 Hastelloy prefabricated pipes have advantages such as stable material quality, excellent mechanical properties, and good corrosion resistance. The C276 Hastelloy alloy prefabricated pipes produced by Enfei Pipeline Equipment Cangzhou Co., Ltd. cover various specifications and sizes, and can provide customized services according to customer needs.

The C276 Hastelloy prefabricated pipeline products of Enfei Pipeline Equipment Cangzhou Co., Ltd. have undergone multiple inspections and tests, meeting relevant national quality standards and environmental requirements, and have been recognized and trusted by a large number of customers. Enfei Pipeline Equipment Cangzhou Co., Ltd. will continue to provide customers with better product quality and services, and promote the development of pressure pipeline systems.

5、 Conclusion

C276 Hastelloy is a material with extremely strong corrosion resistance, and C276 Hastelloy prefabricated pipelines play an important role in chemical pipeline systems. Enfei Pipeline Equipment Cangzhou Co., Ltd.’s C276 Hastelloy alloy prefabricated pipeline products have stable quality, excellent performance, and good corrosion resistance and applicability. During the welding process, attention should be paid to controlling relevant parameters to ensure welding quality and weld performance. Enfei Pipeline Equipment Cangzhou Co., Ltd. will continue to be committed to product research and development and improvement, providing customers with higher quality products and services.

1、 Characteristics of C276 Hastelloy Prefabricated Pipeline

C276 Hastelloy is a type of cobalt based alloy, which has characteristics such as acid resistance, alkali resistance, high temperature resistance, and corrosion resistance. It is widely used in fields such as chemical engineering, metallurgy, electronics, aviation, etc. C276 Hastelloy prefabricated pipelines have become an important component of chemical pipeline systems due to their excellent performance characteristics. Its main characteristics are as follows:

1. Strong corrosion resistance: C276 Hastelloy is an alloy with extremely strong corrosion resistance, which can withstand the erosion of various corrosive media such as acids, alkalis, and salts, and has excellent corrosion resistance.

2. Good high-temperature stability: C276 Hastelloy alloy can still maintain its stable performance at high temperatures, with a wide temperature range and can adapt to various complex environments.

3. High strength: C276 Hastelloy alloy has high strength and can withstand certain pressure and weight.

4. Good toughness and plasticity: C276 Hastelloy alloy has good toughness and plasticity, making it easy to process and shape.

2、 Manufacturing Process of C276 Hastelloy Prefabricated Pipeline

The manufacturing process of C276 Hastelloy prefabricated pipelines mainly adopts two methods: forging and rolling. The forging method is to heat the raw materials to a certain temperature and place them on a forging machine for processing, in order to produce prefabricated pipes with standardized shapes. The rolling method involves squeezing the raw material into a circular shape, and after multiple pipe expansion processes, it is processed into prefabricated pipes with standardized shapes. The specific steps of the manufacturing process are as follows:

1. Melting raw materials: Add C276 Hastelloy raw materials to the furnace for melting until they become liquid.

2. Casting billet: pour molten liquid alloy into the billet to make it Free cooling and form the billet.

3. Forging or rolling processing: Heat the casting billet to an appropriate temperature, and process it into a prefabricated pipeline of standard shape through forging or rolling.

4. Testing and Inspection: Strictly test and inspect each prefabricated pipeline to ensure the quality of the product.

5. Sizing treatment: For prefabricated pipes that have already been processed and formed, perform sizing treatment to better meet user needs in terms of performance.

6. Packaging and transportation: Package and transport the finished product to ensure that it will not be damaged or deformed.

3、 Welding Process of C276 Hastelloy Prefabricated Pipeline

The welding processes of C276 Hastelloy prefabricated pipes mainly include manual arc welding, argon arc welding and plasma welding, of which manual arc welding is suitable for small-scale production and maintenance; Argon arc welding and plasma welding are suitable for large-scale production and high-quality welding of workpieces. The welding process of C276 Hastelloy prefabricated pipeline should pay attention to the following matters:

1. Before welding, the surface should be cleaned to remove dirt and oxides.

2. Select tungsten electrode, suitable welding wire, and protective gas to ensure welding quality.

During the welding process, control the welding parameters and stability of the arc, and use shielding materials to protect the weld seam during welding.

4. After welding, heat treatment can be carried out to ensure the quality and performance of the weld seam.

4、 C276 Hastelloy prefabricated pipeline from Enfei Pipeline Equipment Cangzhou Co., Ltd

Enfei Pipeline Equipment Cangzhou Co., Ltd. is a professional enterprise that produces high-end pressure pipeline systems. Its C276 Hastelloy prefabricated pipes have advantages such as stable material quality, excellent mechanical properties, and good corrosion resistance. The C276 Hastelloy alloy prefabricated pipes produced by Enfei Pipeline Equipment Cangzhou Co., Ltd. cover various specifications and sizes, and can provide customized services according to customer needs.

The C276 Hastelloy prefabricated pipeline products of Enfei Pipeline Equipment Cangzhou Co., Ltd. have undergone multiple inspections and tests, meeting relevant national quality standards and environmental requirements, and have been recognized and trusted by a large number of customers. Enfei Pipeline Equipment Cangzhou Co., Ltd. will continue to provide customers with better product quality and services, and promote the development of pressure pipeline systems.

5、 Conclusion

C276 Hastelloy is a material with extremely strong corrosion resistance, and C276 Hastelloy prefabricated pipelines play an important role in chemical pipeline systems. Enfei Pipeline Equipment Cangzhou Co., Ltd.’s C276 Hastelloy alloy prefabricated pipeline products have stable quality, excellent performance, and good corrosion resistance and applicability. During the welding process, attention should be paid to controlling relevant parameters to ensure welding quality and weld performance. Enfei Pipeline Equipment Cangzhou Co., Ltd. will continue to be committed to product research and development and improvement, providing customers with higher quality products and services.