The important application of ASTM A182 F51 Flanges in marine engineering projects.

1、 Introduction

Ocean engineering refers to engineering activities and projects carried out in the marine environment. It covers a wide range of fields, including seabed oil and gas exploitation, seabed mineral resources development, marine energy utilization, marine surveying and exploration, marine environmental protection, marine transportation, marine buildings and structures, marine biotechnology, etc.

The characteristics of ocean engineering are carried out in complex marine environments, involving the influence of natural conditions such as ocean waves, tides, wind, and currents. Ocean engineering needs to consider the corrosion resistance of ocean engineering materials, the wind resistance, wave resistance, and impact resistance of structures, as well as the reliability and safety of engineering equipment.

The development of ocean engineering is of great significance for the strategic layout and sustainable development of the national economy. It can bring enormous potential and opportunities for energy security, economic development, technological innovation, and environmental protection. At the same time, the development of ocean engineering also faces technical challenges, engineering risks, and environmental impacts, which require comprehensive consideration of various factors to achieve sustainable development. TheASTM A182 F51 Flanges is highly praised for its excellent corrosion resistance and mechanical properties, and is widely used in the production and construction of marine engineering. This article will introduce the application and importance of ASTM A182 F51 Flanges in marine engineering projects, production process and performance, as well as its performance in corrosion resistance.

2、 Introduction to ASTM A182 F51 Flanges

A182 F51 is a duplex stainless steel, also known as 2205 stainless steel. This material has advantages such as high strength, strong corrosion resistance, and good weldability. At the same time, it has relatively low prices and can replace corrosion-resistant alloys for energy conservation and environmental protection. Therefore, it is widely used in various fields. ASTM A182 F51 Flanges is a pipeline connector that can be used to connect different components such as pipes, flanges, and valves. In the salt lake lithium salt project, the use of A182 F51 material can effectively ensure the flow stability and sealing of the medium in high-temperature and high-pressure environments, while avoiding production accidents and losses caused by equipment and pipeline corrosion.

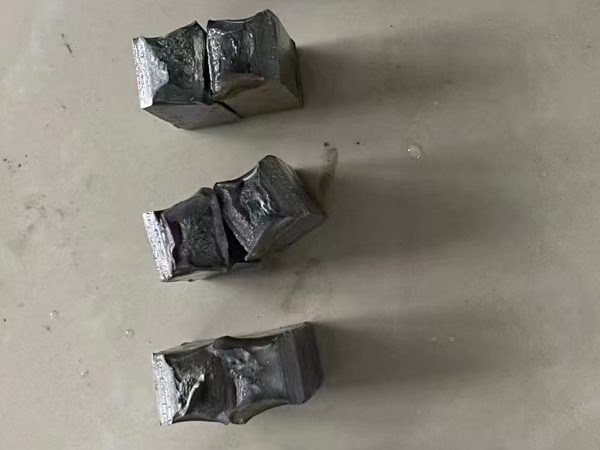

ASTM A182 F51 Flanges Tensile Properties Testing

3、 Background of Ocean Engineering Projects

The application range of ocean engineering is very extensive. It is used for drilling platforms, production facilities, and pipeline systems in subsea oil and gas extraction; In the utilization of marine energy, it is used for offshore wind power generation, Tidal power utilization and marine thermal energy utilization; Used for marine geological exploration and marine ecological investigation in marine surveying and exploration; Used for marine pollution control and marine ecological restoration in marine environmental protection.

4、 Application of ASTM A182 F51 Flanges in Marine Engineering Projects

In the salt lake lithium salt project, ASTM A182 F51 Flanges material is widely used. It is mainly used in connecting components such as pipelines, valves, flanges, and other supporting equipment in marine engineering projects. The following will introduce its applications from three aspects: production process, performance, and corrosion resistance.

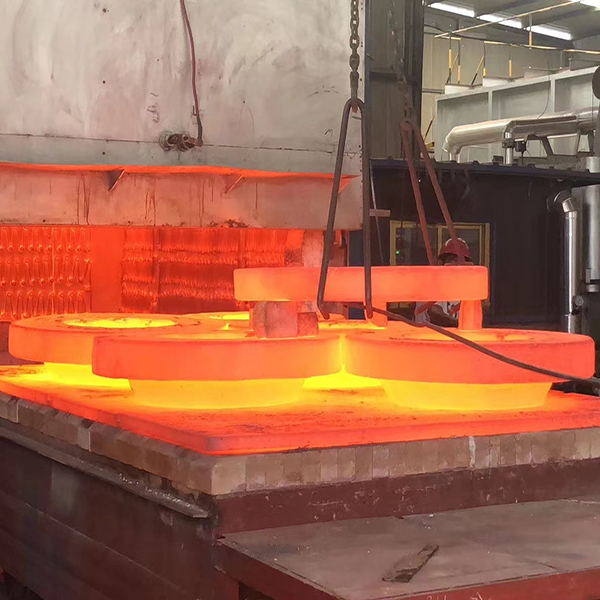

Heat treatment of ASTM A182 F51 Flanges

1. Production process

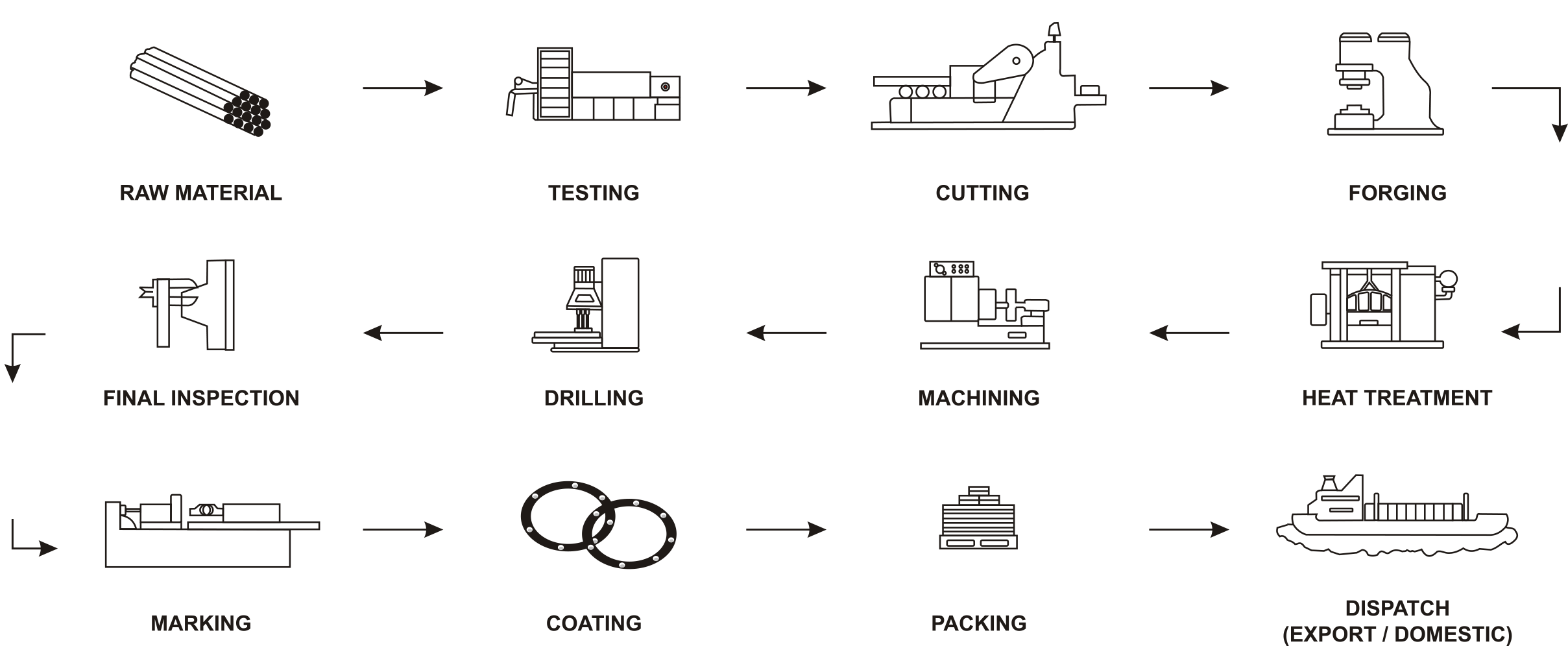

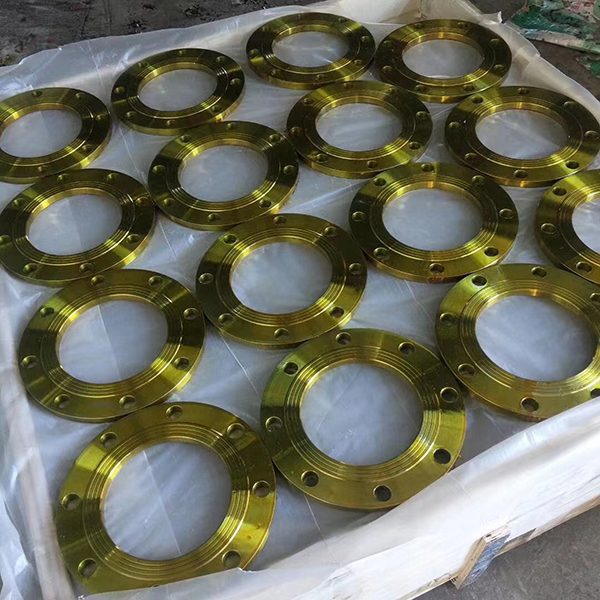

The production of ASTM A182 F51 Flanges requires processes such as melting, ingot casting, and hot rolling. To ensure product quality, other processes such as heat treatment, steel plate cutting, processing, forming, marking, painting, inspection, etc. are also required to produce high-quality flange materials.

ASTM A182 F51 Flanges Chemical Composition

| Grade | UNS | Abbreviation | C% | Mn% | Si% | Cr% | Ni% | Mo% | S% | P% | N% |

| A182 F51 | S31803 | 2205 | 0.03 max | 2 max | 1 max | 21.0-23.0 | 4.5-6.5 | 2.5-3.5 | 0.015 max | 0.035 max | 0.1-0.22 |

| A182 F60 | S32205 | 0.03 max | 2 max | 1 max | 21.0-23.0 | 4.5-6.5 | 2.5-3.5 | 0.015 max | 0.035 max | 0.1-0.22 | |

| A182 F53 | S32750 | 2507 | 0.03 max | 2 max | 1 max | 24.0-26.0 | 6.0-8.0 | 3.0-4.5 | 0.015 max | 0.035 max | 0.24-0.35 |

| A182 F55 | S32760 | Zeron 100 | 0.03 max | 1 max | 1 max | 24.0-26.0 | 6.0-8.0 | 3.0-4.0 | 0.01max | 0.03max | 0.03max |

| A182 F44 | S31254 | 254SMO | 0.02max | 0.03max | 0.7max | 19.5-20.5 | 17.5-18.5 | 6-7 | 0.01max | 0.03max | 0.18-0.25 |

2. Performance

The advantages of ASTM A182 F51 Flanges lie in its high strength, strong corrosion resistance, and good weldability. Specifically manifested in the following aspects:

ASTM A182 F51 Flanges Tensile Properties at Room Temperature

| Grade | UNS | Abbreviation | Tensile strength [MPa] | Yield strength, min,≥[MPa] | Reduction of area, min,≥% | Dichte |

| A182 F51 | S31803 | 2205 | 640-920 | 450 | 22 | 7.8 |

| A182 F60 | S32205 | 640-880 | 450 | 22 | 7.8 | |

| A182 F53 | S32750 | 2507 | 580-800 | 550 | 20 | 7.81 |

| A182 F55 | S32760 | Zeron 100 | 750-895 | 550 | 25 | 7.81 |

| A182 F44 | S31254 | 254SMO | 650-850 | 300 | 35 | 8 |

(1) High strength: The yield strength, tensile strength, and plastic elongation of A182 F51 material are superior to conventional stainless steel materials.

(2) Strong corrosion resistance: The A182 F51 material has strong corrosion resistance, especially in corrosive environments such as high temperature and pressure, saline water, and ocean mining.

(3) Good weldability: The A182 F51 material has excellent welding performance, and will not produce cracks or cause failure of the welding position during the welding process, thereby ensuring the strength and sealing of the connection.

3. Corrosion resistance

The corrosion resistance of ASTM A182 F51 Flanges material is very excellent. After experimental verification, A182 F51 material can be used for a long time in complex environments such as high temperature and pressure, acid alkali solution, salt water, etc. without corrosion. In addition, this material also has good resistance to spot corrosion and intergranular corrosion, which can effectively ensure the safety and reliability of production equipment and pipelines.

5、 Application Cases

Below are three practical examples to introduce the application of ASTM A182 F51 Flanges material in marine engineering projects:

1. In the process flow of marine engineering projects, the flanges and pipelines made of A182 F51 material ensure stable flow of the medium in high-temperature and high-pressure environments, and avoid production accidents and losses caused by equipment and pipeline corrosion.

2. In marine engineering projects, A182 F51 material is applied to various parts of equipment, such as filters and backwash valves used in water treatment equipment, manhole covers, well casing connections, etc., achieving good anti-corrosion and high-pressure resistance.

3. In the electrolysis equipment of marine engineering projects, A182 F51 material is also used to manufacture flanges and pipelines, ensuring the stable flow and sealing of the electrolyte during the production process in high-temperature and high-pressure environments, and avoiding problems such as fluid leakage and oxidation.

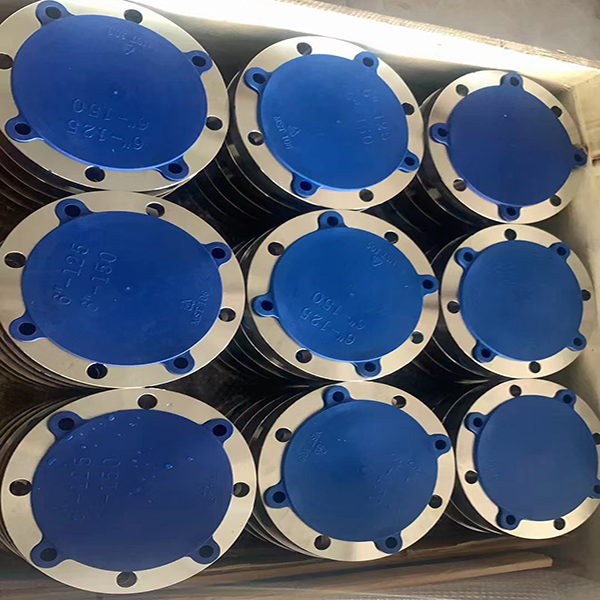

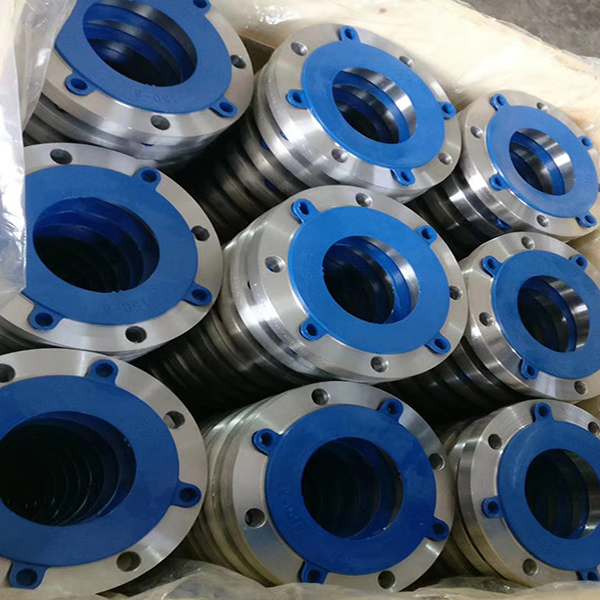

ASTM A182 F51 Flanges packaging and delivery

6、 Conclusion

In marine engineering projects, the ASTM A182 F51 Flanges material has excellent corrosion resistance, high strength, and environmental adaptability, which can effectively resist the erosion of complex environments such as high temperature and pressure, providing critical support for the construction and production of marine engineering projects. In the future, with the continuous focus and investment of the country in the marine engineering industry, the application range of A182 F51 material will be more extensive, and it will also inject strong impetus into the development of China’s marine engineering field.