ASTM A182 F316L Flanges is a high-strength, corrosion-resistant, high-temperature, and low-temperature resistant metal material widely used in important equipment of LNG liquefied natural gas ships. LNG liquefied natural gas carriers are an important means of transporting liquefied natural gas (LNG) from its origin to its destination, ensuring the effective extraction and utilization of global natural gas resources. Due to the low liquefaction temperature of LNG, the transportation process involves the transmission and storage of low-temperature liquid gases. Therefore, the performance of ASTM A182 F316L NACE Flanges is very important.

ASTM A182 F316L Flanges plays an important role in the operation of LNG liquefied natural gas ships. They are mainly used to connect various equipment and pipelines, such as liquefied gas storage tanks, pump stations, steam boilers, etc., to ensure the transportation and storage of liquid gases at different temperatures and pressures. The high strength and corrosion resistance of ASTM A182 F316L Flanges ensure the safety and reliability of LNG liquefied natural gas ships in harsh marine environments. In addition, the ASTM A182 F316L Flanges also has good weldability and machinability, which facilitates the design and manufacturing of ships.

However, in low-temperature environments, the performance of ASTM A182 F316L NACE Flanges will be affected. Low temperature can cause the hardness and strength of stainless steel materials to deteriorate, making it prone to deformation and plastic failure problems such as brittle fracture. At the same time, in liquid gas storage tanks, the interaction between temperature and pressure changes may also cause structural fatigue problems such as cold fatigue and thermal fatigue. More seriously, at extreme low temperatures, small cracks and defects can easily lead to material damage and failure.

To address these issues, LNG liquefied natural gas ships typically use low-temperature stainless steel materials and low-temperature stainless steel flanges, such as A182 F304L and F316L. These materials contain the main components of low-temperature steel, such as chromium, nickel, and molybdenum, which can improve the toughness and corrosion resistance of the material and reduce its brittleness. At the same time, adopting appropriate manufacturing and welding processes can effectively improve the low-temperature durability and reliability of stainless steel flanges.

1、 Application of ASTM A182 F316L Flanges in Different Industries

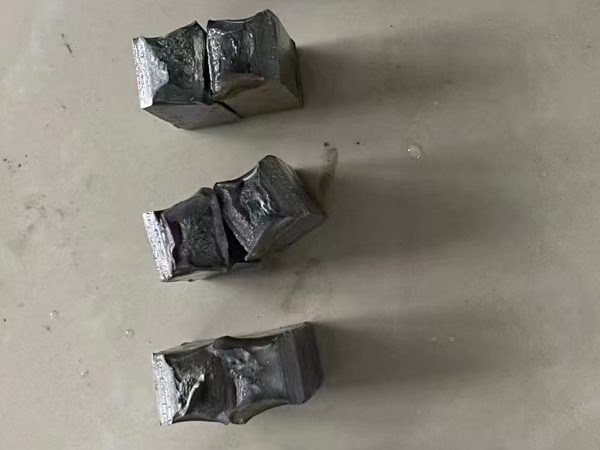

ASTM A182 F316L Flanges Tensile Properties Testing

1. Chemical industry

ASTM A182 F316L NACE Flanges are widely used in the chemical industry due to the high requirements for corrosion resistance of equipment in the chemical production process. ASTM A182 F316L Flanges is used in manufacturing equipment such as reactors, storage tanks, pump valves, and pipelines, and corrosive substances can be frequently recycled without causing damage to the equipment.

2. Petroleum industry

ASTM A182 F316L Flanges is mainly used in the petroleum industry for producing equipment such as well pipes, protective casings, and drilling pipes. They need to withstand very high pressure and temperature, and must be able to prevent rust and corrosion, so the stainless steel flange material used for these equipment often needs to choose the best quality ASTM A182 F316L Flanges.

3. Petrochemical industry

In the petrochemical industry, ASTM A182 F316L Flanges are mainly used for manufacturing separation equipment, processing equipment, and storage and transportation equipment. These devices often need to work in high temperature, high pressure, and corrosive environments, while also maintaining a high level of safety. ASTM A182 F316L Flanges can ensure the corrosion resistance and high safety of the equipment.

4. Pharmaceutical industry

NORSOK M-650 ASTM A182 F316L Flanges are also widely used in the pharmaceutical industry. In the pharmaceutical manufacturing process, materials not only need to ensure purity and cleanliness, but also need to have good machinability, so stainless steel flanges are a good choice. ASTM A182 F316L Flanges also have good corrosion resistance, high temperature resistance, and weldability, making them widely used in the manufacturing of equipment and containers in the pharmaceutical industry.

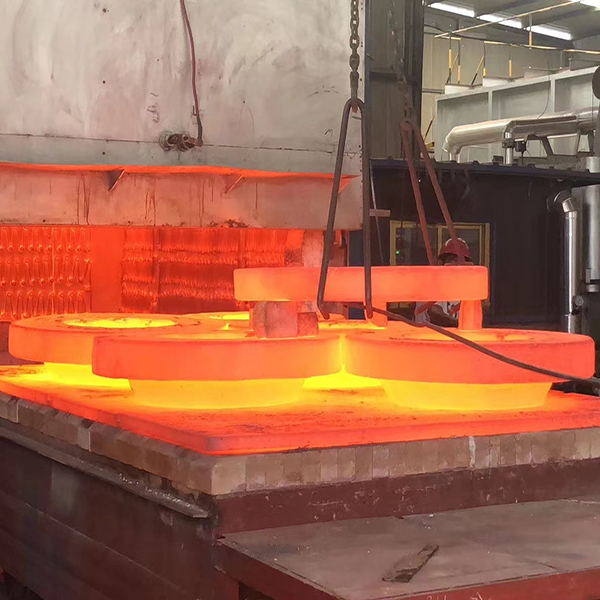

Heat treatment of ASTM A182 F316L Flanges

2、 Standard for stainless steel flanges

1. International standards

Internationally, the standards for stainless steel flanges mainly include JIS, DIN, ISO, and BS. These standards usually have strict quality inspection standards to ensure that the quality of materials meets the requirements. And stainless steel flanges that use international standards can be used globally.

2. American Standards

Stainless steel flange standards for American systems are usually developed by the American Petroleum Institute (API) or the American Standards Technical Committee (ASTM). These standards cover the specifications and dimensions of many stainless steel flanges, and have corresponding quality inspection standards.

3. Japanese standards

In Japan, the main standard for stainless steel flanges is JIS. These standards cover the specifications and dimensions of many stainless steel flanges, and have corresponding quality inspection standards.

3、 Stainless steel flange type

1. Butt welding flange

Butt welded flanges are the most common type of stainless steel flange. It is composed of a flange plate and a set of flange rings. The flange ring is mainly used to connect pipelines, while the flange plate is used to connect equipment and pipelines. Butt welding flanges usually require the use of welding equipment to secure them to pipelines or equipment.

2. Spiral waist flange

The spiral waist flange is composed of a flange plate and a set of spiral waist. Unlike butt welded flanges, spiral waist flanges typically do not require welding, but instead use a set of spiral waists to secure them to the pipeline or equipment.

3. Blind flange

Blind flange is a closed type stainless steel flange. It is used to block holes in pipelines or equipment, usually when replacing pipeline valves or other equipment.

4. Butterfly valve flange

Butterfly valve flanges are also a common type of stainless steel flange. It is a butterfly valve installed in the pipeline and connected to the pipeline through flange components including the valve.

ASTM A182 F316L Flanges Chemical Composition

| Grade | UNS | C% | Mn% | Si% | S% | P% | Cr% | Ni% | Mo% |

| F304L | S30403 | 0.30 max | 2.00 max | 1.00 max | 0.03 max | 0.045 max | 18.00-20.00 | 8.00-13.00 | |

| F316L | S31603 | 0.30 max | 2.00 max | 1.00 max | 0.03 max | 0.045 max | 16.00-18.00 | 10.00-15.00 | 2.00-3.00 |

| F321 | S32100 | 0.08 max | 2.00 max | 1.00 max | 0.03 max | 0.045 max | 17.00-19.00 | 9.00-12.00 | |

| F310 | S31000 | 0.25 max | 2.00 max | 1.00 max | 0.03 max | 0.045 max | 24.00-26.00 | 19.00-22.00 | |

| F347 | S34700 | 0.08 max | 2.00 max | 1.00 max | 0.03 max | 0.045 max | 17.00-20.00 | 9.00-13.00 | |

| F316Ti | S31653 | 0.08 max | 2.00 max | 1.00 max | 0.03 max | 0.045 max | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 |

| F904L | N08904 | 0.02 max | 2.00 max | 1.00 max | 0.03 max | 0.04 max | 19.00-23.00 | 23.00-28.00 | 4.00-5.00 |

| F310MoLN | S31050 | 0.03 max | 2.00 max | 0.4 max | 0.015 max | 0.03 max | 24.00-26.00 | 21.00-22.00 | 2.00-3.00 |

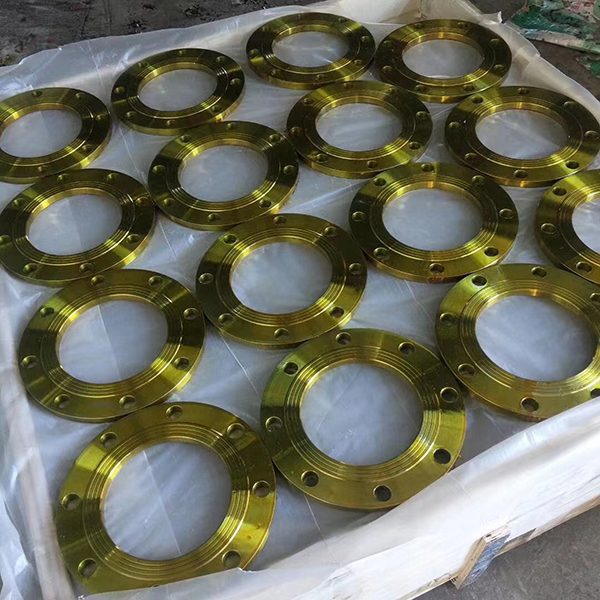

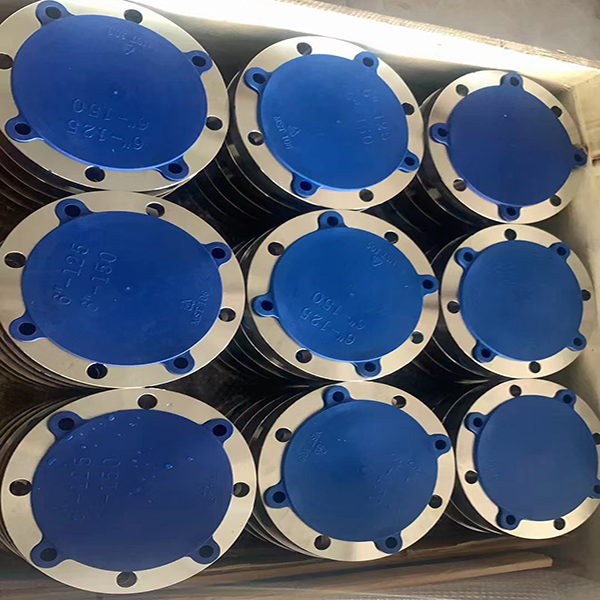

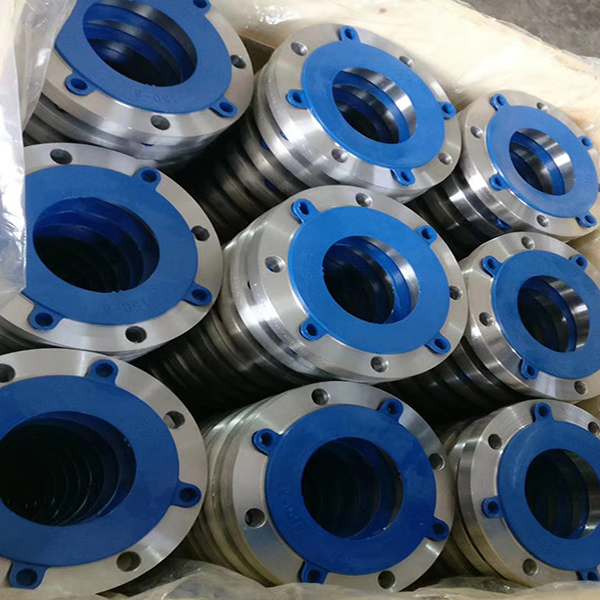

ASTM A182 F316L Flanges packaging and delivery

4、 Summary

This article focuses on the application of NORSOK M-650 ASTM A182 F316L Flanges in industries such as chemical, petroleum, petrochemical, and pharmaceutical industries, and introduces the standards and types of stainless steel flanges. Stainless steel flanges can be manufactured with different materials, standards, and types according to different application scenarios. Regardless of the type of stainless steel flange, its key advantage lies in its material selection, which can achieve excellent corrosion resistance, high temperature resistance, processability, and weldability.