We ENFEI provide kinds of Pressure Vessels Heads, such as Torispherical Head,Dish End,Dish Head,Pressure Vessel head,Torispherical Dish Head; Elliptical Heads, elliptical head, elliptical head price, boiler elliptical end cap; Hemisphere Head, dished end caps, Hemispherical Dished Ends, Industrial Dish End, hemisphere tank heads, Hemisphere ends for tanks parts,water heater hemisphere heads,hemispherical dished ends.

Pressure Vessels Torispherical Heads Pressure Vessels Hemispherical Heads

Pressure Vessels Flat Heads Pressure Vessels Ellipsoidal Heads

The head of a pressure vessel is a structural component used to close the vessel, usually located in one of the two openings of the vessel, for the inlet and outlet, maintenance, and cleaning of the vessel. According to different shapes and design requirements, there are several common types of pressure vessel heads:

1. Flat Head: Flat heads are the simplest and most common type of head, with a flat shape and are typically used for low-pressure or small containers. Flat heads have simple manufacturing processes and lower costs.

2. Spherical Head: The shape of the arc head is similar to a partial sphere and has good strength and pressure resistance. Arc heads are usually used for high-pressure or large vessels and can withstand high internal pressure.

3. Ellipsoidal Head: The shape of an elliptical head is approximately an ellipse, with a moderate cross-sectional curvature and good stress distribution. Elliptical heads are commonly used for containers with medium pressure and volume.

4. Spherical Head: The spherical head combines the characteristics of arc head and elliptical head, and is a common type of head. Ball drum heads are commonly used in medium and high pressure vessels and mechanical equipment, with good strength and stress distribution.

In addition to the common types of heads mentioned above, there are also some special shaped heads, such as conical heads, flat ball heads, tube plate heads, etc., which can be selected based on specific container design and usage requirements.

When selecting and designing the head, it is necessary to consider factors such as the working pressure, working temperature, container material, container shape, and connection method on the container. In addition, it is necessary to design and manufacture according to applicable standards and specifications, such as the ASME Boiler and Pressure Vessel Code, to ensure the safety, reliability, and compliance with regulatory requirements of the head.

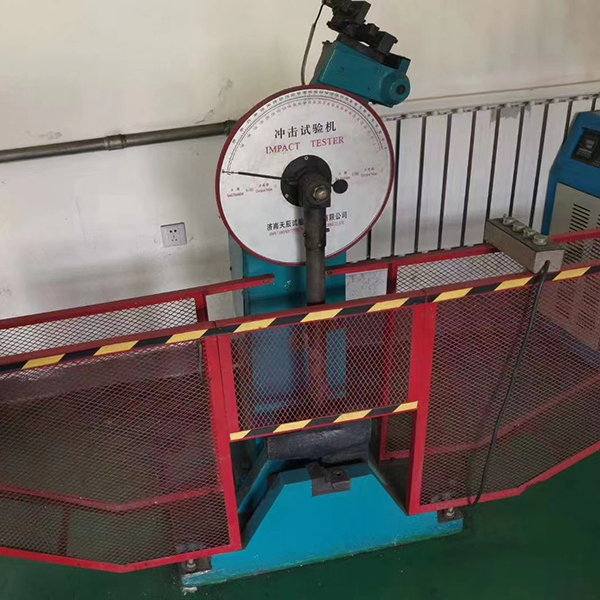

Mechanical properties and welding test of Pressure Vessels Heads

Pressure vessel heads are widely used in fields such as shipbuilding, petrochemical industry, and offshore platforms. The following are their common applications in these fields:

1. Ship construction: In ship construction, pressure vessel heads are usually used for storing and transporting liquids or gases in containers such as oil tanks, water tanks, gas tanks, etc. These heads are used to ensure the sealing of liquids or gases inside the ship, as well as to withstand internal pressure changes during ship operation.

Heat treatment of Pressure Vessels Heads

2. Petrochemical industry: In the petrochemical industry, pressure vessel heads are used for storing and processing petroleum and its derived products, such as tanks, reactors, separators, etc. These heads withstand chemical reactions and process operations under high pressure and high temperature conditions, ensuring the sealing and safety of the system.

3. Offshore platforms: In the construction of offshore platforms, pressure vessel heads are widely used for storing and processing offshore oil and natural gas resources. Pressure vessels on offshore platforms are used for storing and transporting oil and its derivatives, such as oil and gas storage tanks, separators, and heating furnaces. These heads can withstand harsh conditions in the marine environment, including high pressure, high temperature, seawater corrosion, and wave impact.

The application of pressure vessel heads in the above fields requires characteristics such as high strength, corrosion resistance, high temperature resistance, and reliable sealing. Therefore, high-quality materials such as stainless steel, alloy steel, and nickel based alloys are usually used for manufacturing. At the same time, according to specific application requirements and standard requirements, the head needs to be designed, manufactured, and inspected according to specifications to ensure its safe and reliable use.