A815 S32750 Piping Fittings are important applications for Qinghai Salt Lake Potash’s 40000 ton/year basic lithium salt integration project.

1、 Project Overview

Located in Ledu District, Haidong City, Qinghai Salt Lake Potash’s 40000 ton/year basic lithium salt integration project, with a total investment scale of 7.098 billion yuan, is one of the important projects for the development and utilization of lithium resources in China. The project mainly includes lithium salt separation, battery grade Lithium carbonate production, lithium metal preparation and other processes. It is estimated that the annual output of lithium salt will be 40000 tons, filling the gap of domestic basic lithium salt production.

2、 Introduction to Pipeline System

The 40000t/a basic lithium salt integration project of Qinghai Salt Lake Potash involves the gas, liquid and solid systems of high concentration hydrochloric acid, sodium hydroxide, sodium bicarbonate and other strong acid and alkali media as well as the transportation system of high concentration lithium salt solution. The pipeline system plays a crucial role in the smooth progress of the entire production process. Therefore, the selection of pipe material and performance requirements are very high.

3、 Introduction to A815 S32750 Piping Fittings

Duplex 2507 is a linear material that combines ferrite and austenite. Due to its excellent formability of ferrite, good corrosion resistance of austenite, and excellent toughness, it is widely used in fields such as chemical engineering, aviation, shipbuilding, and marine engineering.

2、 Characteristics of A815 S32750 Piping Fittings

S32205 duplex stainless steel is a type of stainless steel with a ferrite and austenite structure, which has relatively high corrosion resistance, stress corrosion resistance, strength and toughness, and is widely used in fields such as petroleum, chemical, marine engineering, and medical treatment.

ASTM A815 S32750 Piping Fittings Chemical Composition

| UNS | Abbreviation | C% | Mn% | Si% | Cr% | Ni% | Mo% | S% | P% | N% |

| S31803 | 2205 | 0.03 max | 2 max | 1 max | 21.0-23.0 | 4.5-6.5 | 2.5-3.5 | 0.015 max | 0.035 max | 0.1-0.22 |

| S32205 | 0.03 max | 2 max | 1 max | 21.0-23.0 | 4.5-6.5 | 2.5-3.5 | 0.015 max | 0.035 max | 0.1-0.22 | |

| S32750 | 2507 | 0.03 max | 2 max | 1 max | 24.0-26.0 | 6.0-8.0 | 3.0-4.5 | 0.015 max | 0.035 max | 0.24-0.35 |

| S32760 | Zeron 100 | 0.03 max | 1 max | 1 max | 24.0-26.0 | 6.0-8.0 | 3.0-4.0 | 0.01max | 0.03max | 0.03max |

| S31254 | 254SMO | 0.02max | 0.03max | 0.7max | 19.5-20.5 | 17.5-18.5 | 6-7 | 0.01max | 0.03max | 0.18-0.25 |

A815 S32750 Piping Fittingss have the following advantages:

1. It has high corrosion resistance and can operate safely in medium environments with strong acids, alkalis, and high salinity.

2. It has high strength and toughness, and can withstand heavy load work in high-temperature and high-pressure environments.

3. It has good processing and welding performance, making it convenient for processing and assembly during the production process.

4. It has a long service life and good environmental performance, which can greatly reduce production costs and environmental pollution.

ASTM A815 S32750 Piping Fittings Tensile Properties at Room Temperature

| UNS | Abbreviation | Tensile strength [MPa] | Yield strength, min,≥[MPa] | Reduction of area, min,≥% | Dichte |

| S31803 | 2205 | 640-920 | 450 | 22 | 7.8 |

| S32205 | 640-880 | 450 | 22 | 7.8 | |

| S32750 | 2507 | 580-800 | 550 | 20 | 7.81 |

| S32760 | Zeron 100 | 750-895 | 550 | 25 | 7.81 |

| S31254 | 254SMO | 650-850 | 300 | 35 | 8 |

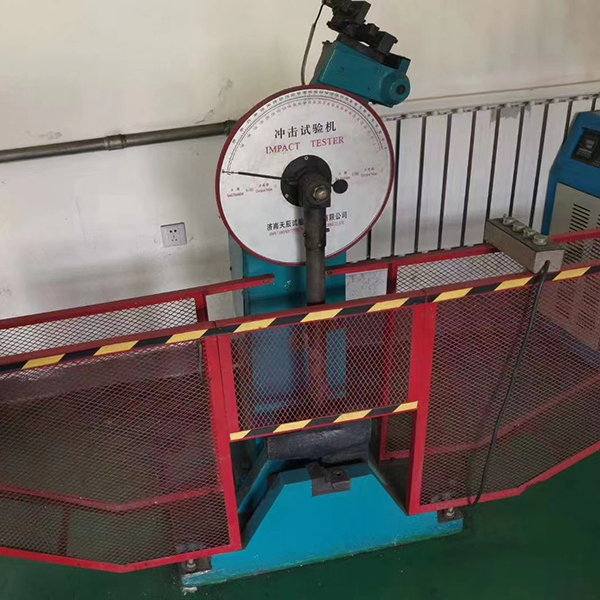

Mechanical properties and welding test of ASTM A815 S32750 Piping Fittings

4、 Application of ASTM A815 S32750 Piping Fittings in the basic lithium salt integration project of Qinghai Salt Lake Potash

1. Pipeline system for transporting high concentration acid and alkali media

In the basic lithium salt integration project of Qinghai Salt Lake Potash, it is necessary to transport high concentration hydrochloric acid, sodium hydroxide, sodium bicarbonate and other strong acid and alkali media, which will cause serious corrosion to general steel, copper and other materials. However, using A815 S32750 Piping Fittings can effectively solve this problem, ensuring the safe operation of the pipeline system and improving production efficiency.

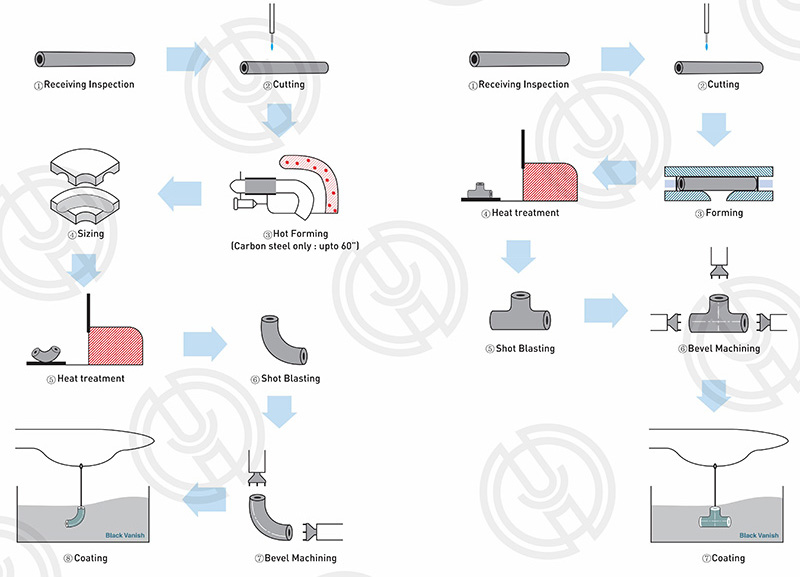

Heat treatment of ASTM A815 S32750 Piping Fittings

2. Pipeline system for conveying high concentration lithium salt solution

In the basic lithium salt integration project of Qinghai Salt Lake Potash, it is necessary to transport high concentration lithium salt solution. The pH value of this solution is very high, and using ordinary steel for transportation can cause serious corrosion. The A815 S32750 Piping Fittings have high corrosion resistance, which can ensure the reliability and stability of the pipeline system during the transportation of high concentration lithium salt solution.

ASTM A815 S32750 Piping Fittings inspection

3. High temperature and high pressure medium conveying system

In the production process of Qinghai Salt Lake Potash’s basic lithium salt integration project, it is often necessary to involve the transportation of high-temperature and high-pressure media, such as water vapor in the vaporizer, phase change steam, etc. A815 S32750 Piping Fittings have high strength and toughness, and can withstand heavy loads in high temperature and high pressure environments, thereby ensuring the safe and reliable operation of the pipeline system.

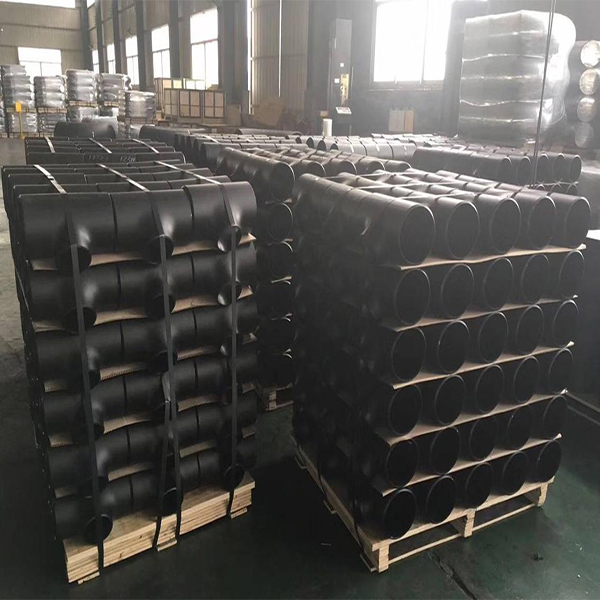

ASTM A815 S32750 Piping Fittings packaging and delivery

5、 Conclusion

ASTM A815 S32750 Piping Fittings have very important application value in the basic lithium salt integration project of Qinghai Salt Lake Potash. It has excellent corrosion resistance, strength, and toughness, and can ensure the safe and reliable operation of pipeline systems in environments such as high concentration acid and alkali media, high concentration lithium salt solution transportation, and high-temperature and high-pressure media transportation. Duplex 2507 pipe fittings have broad application prospects in fields such as chemical, aviation, and marine engineering in the future.