API 6A TYPE 6BX flange and blind plate is a wellhead equipment connection component defined in the ANSI/API Spec 6A specification, used to connect pipeline systems and valve equipment between oil and gas wellhead equipment.

The API 6A TYPE 6BX standard is a pipeline connection standard applied to the petroleum and natural gas industry in high-pressure and ultra-high-pressure environments. The flanges and blind plates in this standard are produced through high-pressure forging to ensure their safety and reliability in high-pressure environments.

The following are some characteristics and applications of API 6A TYPE 6BX standard flanges and blind plates:

1. High pressure capability: API 6A TYPE 6BX standard flanges and blind plates can withstand working pressures up to 20000 psi (1379 bar), suitable for high-pressure and ultra-high-pressure oil and gas fields.

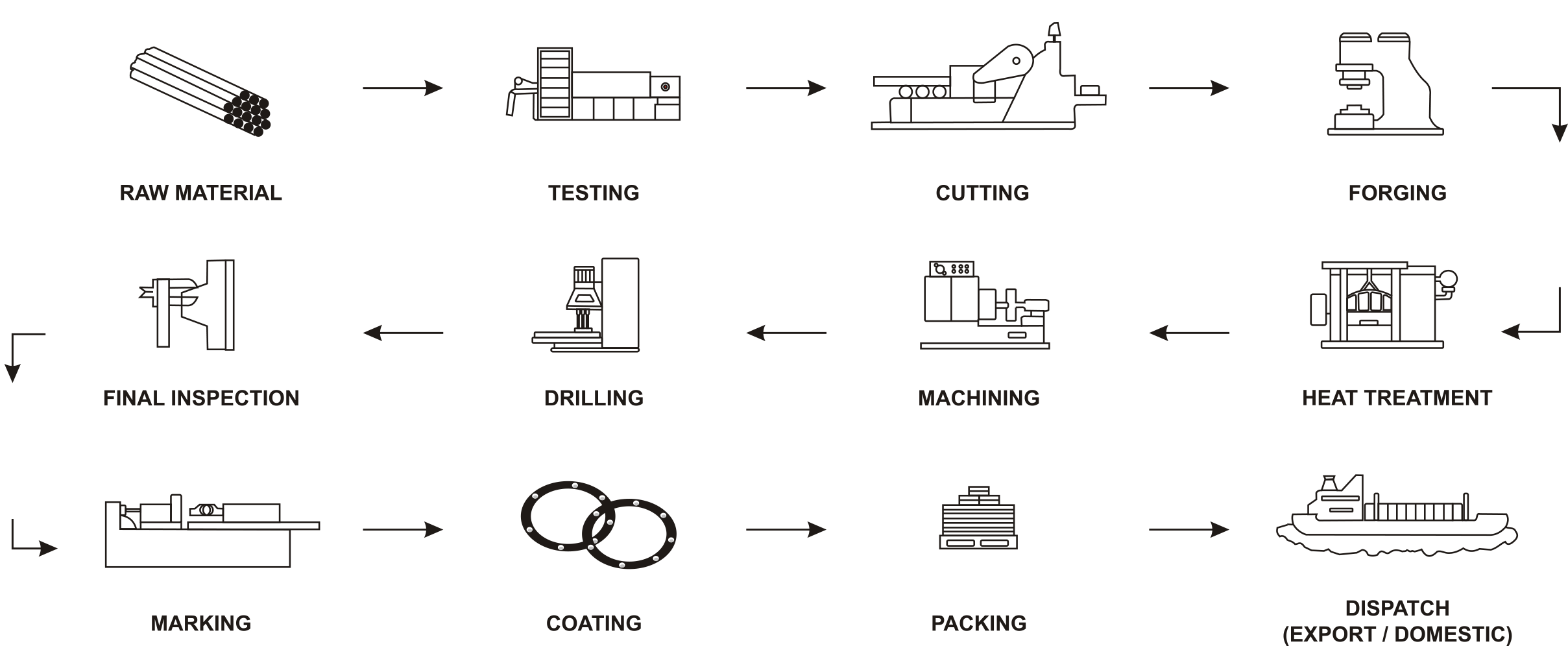

2. Forging manufacturing: According to the requirements of API 6A standard, TYPE 6BX flanges and blind plates need to be manufactured using high-pressure forging process to ensure their strength and durability in high-pressure environments.

3. Strict quality requirements: The API 6A standard has strict requirements for the material, size, strength, and quality of flanges and blind plates to ensure that they meet the application requirements in high-pressure environments.

4. Application field: API 6A TYPE 6BX standard flanges and blind plates are widely used for high-pressure pipeline connections in fields such as oil and gas exploration, transportation, and processing. They are commonly used in oil wells, oil gas separators, flow meters, pressure vessels, and other equipment and systems that require high-pressure sealing and connection.

ANSI/API Spec 6A is a specification jointly developed by the American National Standards Institute (ANSI) and the American Petroleum Institute (API) to regulate the design, manufacturing, and testing requirements of wellhead equipment and valves in the oil and gas industry.

The ANSI/API Spec 6A specification covers the following:

1. Design requirements: Standardized the design requirements for wellhead equipment and valves, including dimensions, materials, strength, corrosion resistance, sealing performance, and other aspects. These requirements aim to ensure that the equipment can operate safely under high pressure, high temperature, and harsh environments.

2. Manufacturing requirements: Standardized the manufacturing requirements for wellhead equipment and valves, including material selection, processing technology, welding requirements, etc. Manufacturers must comply with the requirements in the specifications to ensure the quality and reliability of their products.

3. Testing and Acceptance Requirements: Standardized the testing and acceptance requirements for wellhead equipment and valves. These tests include pressure testing, leakage testing, fire resistance testing, corrosion resistance testing, etc., to ensure that the equipment meets regulatory requirements and can operate safely under predetermined working conditions.

4. Identification and Marking Requirements: Standardized the identification and marking requirements for wellhead equipment and valves, including product identification, size and pressure rating markings, as well as manufacturer identification and certification information.

5. Document and Record Requirements: Standardized the document and record requirements for wellhead equipment and valves, including design documents, manufacturing records, test reports, etc. These documents and records are used to track the quality and manufacturing process of products, and provide necessary audit basis.

The ANSI/API Spec 6A specification is one of the most important standards in the oil and gas industry, ensuring the quality and reliability of wellhead equipment and valves to ensure the safety and efficiency of the production process.

The application of API 6A TYPE 6BX flanges and blind plates in the ANSI/API Spec 6A specification should pay attention to the following points:

1. Flange connection: The API 6A specification specifies different types of flange connections, including the TYPE 6BX flange. TYPE 6BX flange is a high-pressure and high-temperature flange connection used to connect pipeline systems between wellhead equipment. Its design and manufacturing requirements comply with the requirements specified in the specifications, including dimensions, materials, strength, and other aspects.

2. Valve connection: The API 6A specification specifies different types of valve connections, including TYPE 6BX flange connections. The TYPE 6BX flange connection is used to connect the pipeline system from valve equipment to wellhead equipment. It can withstand the requirements of high pressure, high temperature, and harsh working conditions, and ensure the sealing performance and safety of the connection.

3. Blind flange: The API 6A specification also includes provisions for blind flanges. Blind flange is a flange connection component without holes, used to seal interfaces in pipeline systems to prevent fluid leakage or entry. TYPE 6BX blind plate is suitable for TYPE 6BX flange connection, used to close or block the interface of pipeline systems.

4. Design, manufacturing, and testing requirements: The API 6A specification provides detailed requirements for the design, manufacturing, and testing of TYPE 6BX flanges and blind plates. These requirements include dimensions, material specifications, strength calculations, sealing performance, corrosion resistance, and other aspects to ensure that the TYPE 6BX flange and blind plate meet the working requirements under high pressure, high temperature, and harsh environments.

Overall, API 6A TYPE 6BX flanges and blind flanges are important components defined in the ANSI/API Spec 6A specification for connecting and sealing wellhead equipment pipeline systems. These components must comply with the design, manufacturing, and testing requirements specified in the specifications to ensure a safe and reliable working environment and processes.