Abstract:

This paper systematically investigates the mechanical properties and fracture behavior of ASTM A182 F51 flanges through tensile testing and fracture morphology analysis. The results indicate that F51 flanges exhibit unique performance in terms of tensile strength, yield strength, and fracture mechanisms, providing important theoretical foundations and practical guidance for the design, manufacturing, and application of flanges.

Keywords: ASTM A182 F51 Flange; Tensile Strength; Yield Strength; Fracture Morphology; Tensile Test; Fracture Analysis

Introduction:

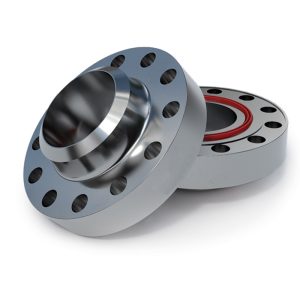

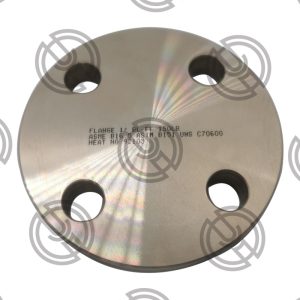

ASTM A182 F51 flanges, as a type of corrosion-resistant alloy flange, are widely used in industries such as oil, chemical, and pharmaceuticals. Their excellent mechanical properties and corrosion resistance make them suitable for extreme environments. This paper aims to evaluate the mechanical properties and fracture mechanisms of F51 flanges through tensile testing and fracture morphology analysis.

Experimental Methods:

Tensile Testing: Tensile tests were conducted on F51 flanges at room temperature according to ASTM E8 standards, recording mechanical properties such as tensile strength and yield strength.

Fracture Morphology Analysis: The fracture surfaces of the tensile specimens were observed and analyzed using Scanning Electron Microscopy (SEM) combined with Energy Dispersive Spectroscopy (EDS).

Analysis of Tensile Strength and Yield Strength Results:

Overview of Tensile Strength and Yield Strength Test Results: F51 flanges demonstrated good mechanical properties during tensile testing, with tensile strength and yield strength meeting the requirements of ASTM A182 standards.

Statistical Analysis of Tensile Strength and Yield Strength: The average tensile strength and yield strength of F51 flanges, as well as the distribution of properties, were determined through statistical analysis of multiple specimens.

Fracture Morphology Analysis:

General Observation of Fracture Morphology: The fracture surfaces of F51 flanges exhibited mixed fracture characteristics, including both brittle and ductile fracture features.

Analysis of Brittle Fracture Region: The brittle fracture region featured river patterns and cleavage planes, which may be related to inclusions in the material, microdefects, and low-temperature conditions.

Analysis of Ductile Fracture Region: The ductile fracture region was characterized by dimples and tear ridges, indicating significant plastic deformation before fracture.

Comprehensive Analysis and Discussion:

The mechanical properties of F51 flanges are closely related to their microstructure and heat treatment processes. Optimizing the heat treatment process can further enhance their mechanical properties.

Fracture morphology analysis reveals the fracture mechanisms of F51 flanges under different conditions, providing important references for improving material properties.

By combining the analysis of tensile strength, yield strength, and fracture morphology, a more comprehensive understanding of the performance of F51 flanges in practical applications can be achieved.

Conclusion:

Through tensile testing and fracture morphology analysis of ASTM A182 F51 flanges, the following conclusions are drawn:

F51 flanges exhibit good mechanical properties in terms of tensile strength and yield strength, meeting the relevant standard requirements.

Fracture morphology analysis indicates that F51 flanges show mixed fracture characteristics during tensile testing, with both brittle and ductile fractures present.

To further improve the mechanical properties and fracture toughness of F51 flanges, attention should be given to inclusions in the material, microdefects, and optimization of the heat treatment process.

This paper provides comprehensive theoretical foundations and practical guidance for the design, manufacturing, and application of ASTM A182 F51 flanges, which is of great significance for improving the reliability and safety of flanges in extreme environments.

By leveraging these strengths, our company is well-positioned to continue delivering high-performance ASTM A182 F51 flanges and other products that meet the demanding needs of the oil, chemical, and pharmaceutical industries, among others. We are committed to being a trusted partner for our clients, providing them with the highest quality products and services that contribute to the success of their projects.