NORSOK M-650 certification requirements for the forging production and processing of ASTM A182 F53 flanges

1、 Introduction to NORSOK M-650 Certification

NORSOK M-650 is a certification standard developed by the Norwegian Organization for Standardization of the Petroleum Industry, which mainly involves the requirements and specifications for the procurement, production, testing, and other metal materials such as steel and copper alloys in the fields of oil and natural gas. This certification standard mainly emphasizes the quality and compliance of materials and is recognized as one of the important certification standards in the international petroleum industry.

2、 Introduction to ASTM A182 F53 flanges

A182 F53 duplex stainless steel is a type of 18Cr-8Ni-3Mo-0.2N duplex stainless steel, which has good corrosion resistance, stress corrosion resistance, strength and toughness, and is widely used in fields such as petroleum, chemical, pharmaceutical, and environmental protection. Due to the unique structural and material characteristics of duplex stainless steel, its special properties and requirements need to be taken into account during manufacturing and processing.

3、 NORSOK M-650 Certification Requirements for ASTM A182 F53 Duplex Stainless Steel Flanges Forging Production and Processing

The requirements for the forging production and processing of A182 F53 duplex stainless steel flanges in NORSOK M-650 certification mainly include the following aspects:

ASTM A182 F53 Flanges Chemical Composition

| Grade | UNS | Abbreviation | C% | Mn% | Si% | Cr% | Ni% | Mo% | S% | P% | N% |

| A182 F51 | S31803 | 2205 | 0.03 max | 2 max | 1 max | 21.0-23.0 | 4.5-6.5 | 2.5-3.5 | 0.015 max | 0.035 max | 0.1-0.22 |

| A182 F60 | S32205 | 0.03 max | 2 max | 1 max | 21.0-23.0 | 4.5-6.5 | 2.5-3.5 | 0.015 max | 0.035 max | 0.1-0.22 | |

| A182 F53 | S32750 | 2507 | 0.03 max | 2 max | 1 max | 24.0-26.0 | 6.0-8.0 | 3.0-4.5 | 0.015 max | 0.035 max | 0.24-0.35 |

| A182 F55 | S32760 | Zeron 100 | 0.03 max | 1 max | 1 max | 24.0-26.0 | 6.0-8.0 | 3.0-4.0 | 0.01max | 0.03max | 0.03max |

| A182 F44 | S31254 | 254SMO | 0.02max | 0.03max | 0.7max | 19.5-20.5 | 17.5-18.5 | 6-7 | 0.01max | 0.03max | 0.18-0.25 |

4. Material procurement and inspection

Steel procurement should comply with ASTM A182 F53 standard and provide material certificates, chemical composition analysis reports, mechanical performance reports, and other documents. The material should undergo ultrasonic testing, magnetic particle testing, and other tests to meet the requirements of NDE Level 2.

ASTM A182 F53 Flanges Tensile Properties Testing

ASTM A182 F53 Flanges Tensile Properties at Room Temperature

| Grade | UNS | Abbreviation | Tensile strength [MPa] | Yield strength, min,≥[MPa] | Reduction of area, min,≥% | Dichte |

| A182 F51 | S31803 | 2205 | 640-920 | 450 | 22 | 7.8 |

| A182 F60 | S32205 | 640-880 | 450 | 22 | 7.8 | |

| A182 F53 | S32750 | 2507 | 580-800 | 550 | 20 | 7.81 |

| A182 F55 | S32760 | Zeron 100 | 750-895 | 550 | 25 | 7.81 |

| A182 F44 | S31254 | 254SMO | 650-850 | 300 | 35 | 8 |

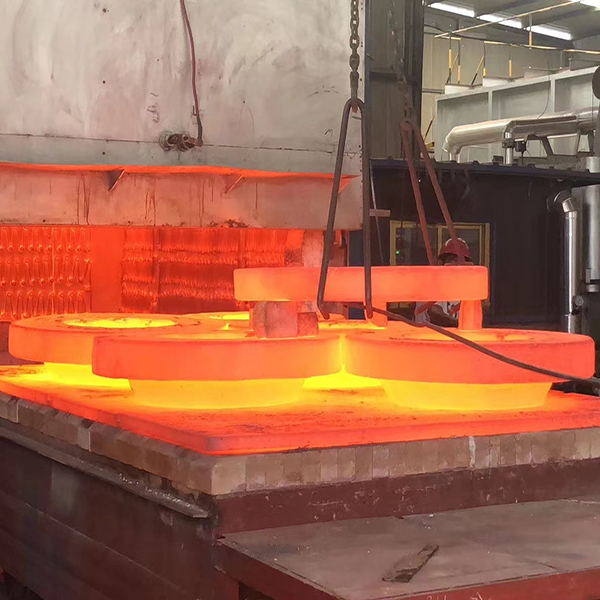

5. Heat treatment requirements

A182 F53 duplex stainless steel requires heat treatment after forging to eliminate residual stress and improve material properties. The heat treatment temperature is 1050 ° C to 1150 ° C, and the cooling method is water quenching or air cooling. Chemical composition and mechanical properties testing are required before and after heat treatment to ensure that the material’s performance meets the requirements.

Heat treatment of ASTM A182 F53 Flanges

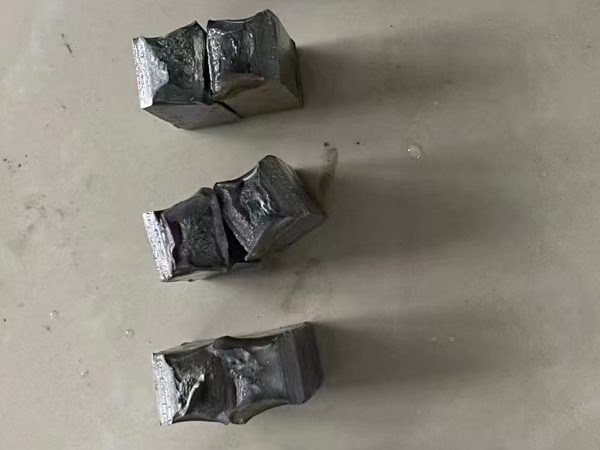

6. Forging process requirements

The forging of A182 F53 duplex stainless steel should be carried out within the range of 1200 ° C to 950 ° C, fully absorbing residual heat during the forging process while ensuring integrity and quality. Before forging, it is necessary to preheat the material and control the temperature and speed during the forging process to ensure the performance and accuracy of the forging. The surface of forgings needs to be polished and treated for corrosion resistance to improve their corrosion resistance and wear resistance.

7. Processing requirements

For the forging of A182 F53 duplex stainless steel flanges, the machining requirements are very high, requiring a certain level of production and manufacturing experience and technical level. Before processing, multiple tests and reviews such as strength, corrosion resistance, and qualification certificates are required to ensure stable and reliable material performance. During the machining process, precision equipment and advanced technology are required to control manufacturing parameters such as temperature, speed, and surface finish, ensuring excellent characteristics such as high dimensional accuracy, good surface quality, and stable performance of flange forgings.

8. Quality assurance system requirements

NORSOK M-650 certification requires forging factories to establish a comprehensive quality system and obtain relevant certifications such as ISO 9001 and OHSAS 18001. Forging factories need to establish a material tracking system to ensure the integrity and quality of each batch of materials. Forgings should undergo 100% UT and MT testing, and the report after testing must comply with NDE Level 2 regulations. At the same time, forging factories should establish comprehensive quality records and retain relevant records for at least 10 years.

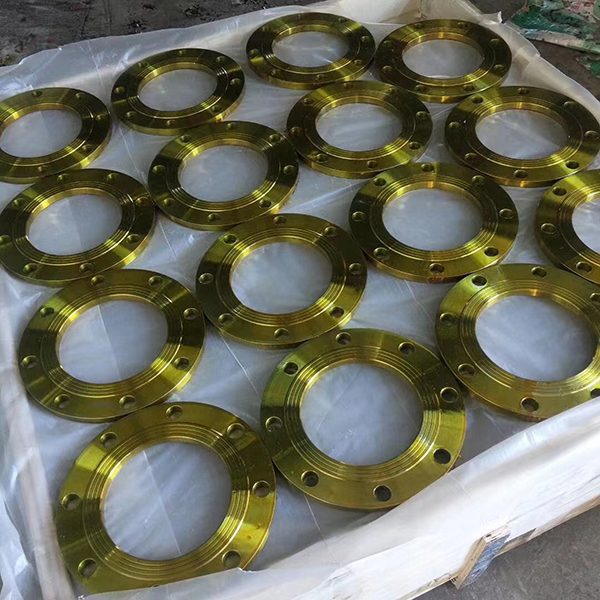

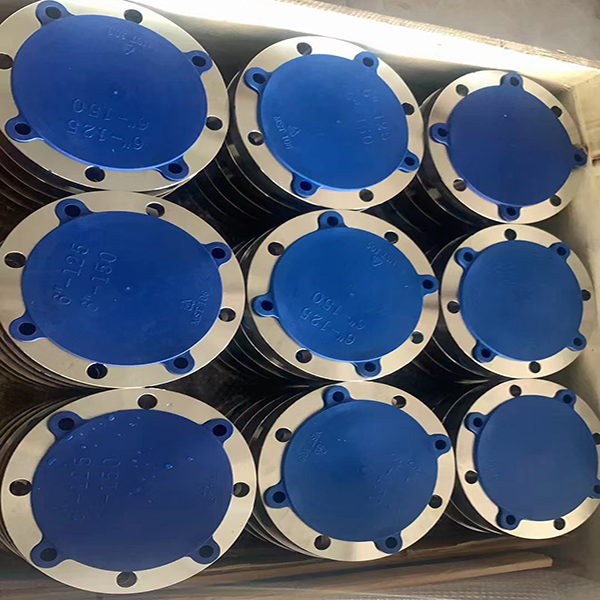

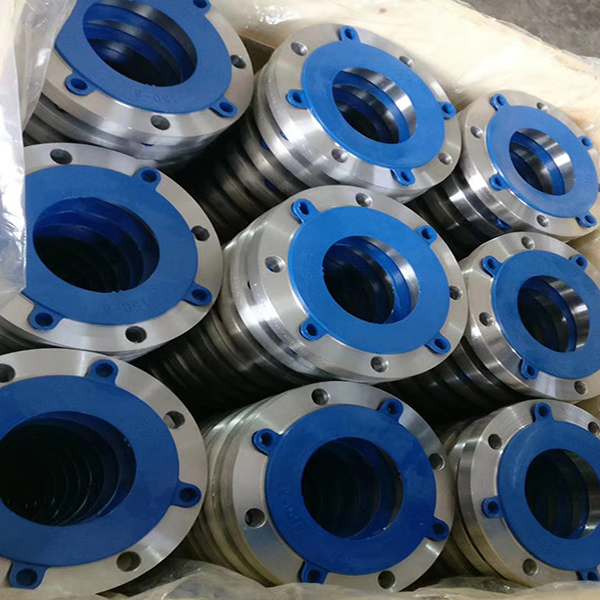

ASTM A182 F53 Flanges packaging and delivery

9、 Conclusion

The forging production and processing of ASTM A182 F53 flanges have very high quality control requirements. In addition to meeting the requirements of ASTM A182 F53 standards, heat treatment, forging, processing, etc., it is also necessary to follow the relevant specifications and requirements specified in NORSOK M-650 certification to ensure the rigor and standardization of the production process. In the production and processing of A182 F53 duplex stainless steel flange forging, it is necessary to strictly grasp the quality and special properties of the material, and adopt high-precision production equipment and advanced technical methods to ensure that the product quality can meet the application requirements and provide reliable guarantee for manufacturing and application in the industrial field