Cangzhou Enfei Pipe Equipment Co., Ltd. is a professional enterprise engaged in the manufacturing of various pipeline accessories. Its main products include flanges, elbows, tees, reducers, pipe caps, etc. Among them, ASTM A350 LF3 Flanges is one of the main products of ENFI pipeline, which adopts advanced production technology and has excellent corrosion resistance, oxidation resistance, and mechanical properties. It is widely used in pipeline systems in industries such as chemical, petroleum, and natural gas.

1、 Basic introduction of ASTM A350 LF3 Flanges

ASTM A350 LF3 Flanges is a low-temperature steel flange, which has better impact resistance and low-temperature performance compared to ordinary carbon steel flanges. Its main components include carbon, manganese, silicon, molybdenum, nickel, and chromium, which comply with ASTM standards and have been widely used internationally.

This type of flange is mainly divided into the following two varieties:

1. Ordinary flange: Its connection method is pressure grade, and the number of flange connecting bolts is determined based on the pressure grade. Its sealing surface is usually of two types: flat and convex.

2. Los buckle flange: Its connection method is to use the nozzle end, clamp, and Los buckle as the basic components, and achieve sealing through the compression of radial gaskets. Using this type of flange can reduce damage to the pipeline.

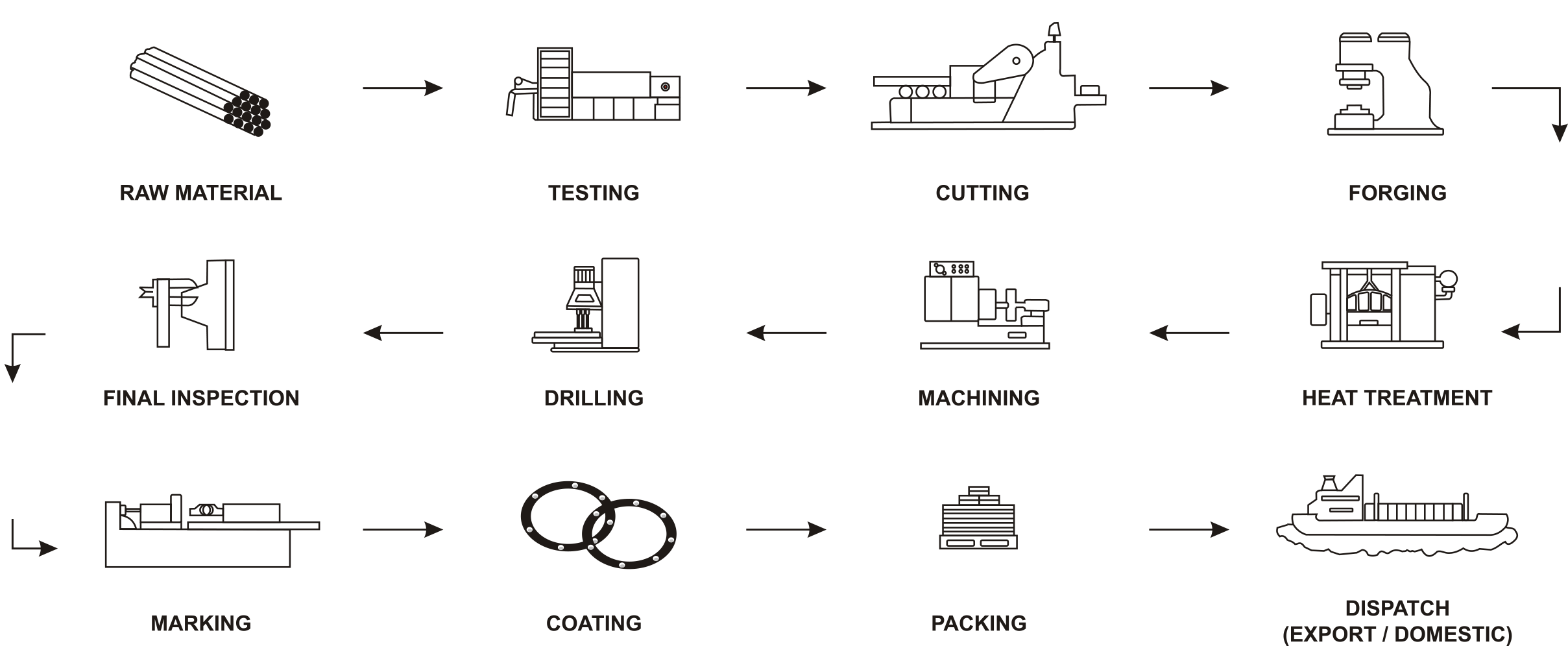

2、 Manufacturing process of ASTM A350 LF3 Flanges

The manufacturing process of the ASTM A350 LF3 Flanges for ENFI pipeline mainly includes the following steps:

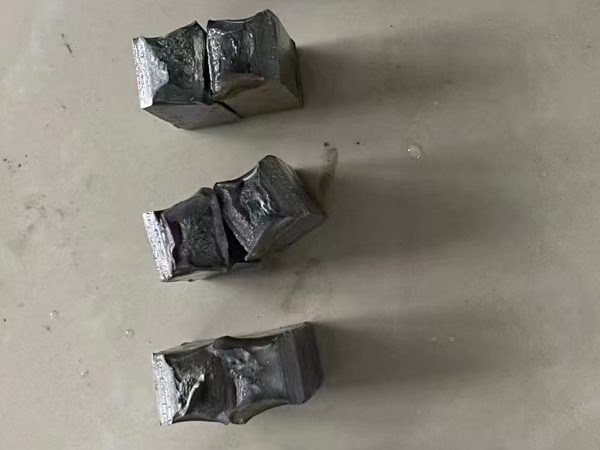

1. Material procurement: The company uses high-quality A350 LF3 steel as raw materials, and each batch of materials undergoes strict quality testing and screening. For unqualified materials, the company will directly scrap them.

Chemical composition of ASTM A350 LF3 Flanges

| Grade | C% | Mn% | Si% | S% | P% | Cr% | Ni% | Mo% |

| LF1 | 0.30 max | 0.6-1.35 | 0.15-0.30 | 0.040 max | 0.035 max | 0.30 max | 0.40 max | 0.12 max |

| LF2 | 0.30 max | 0.6-1.35 | 0.15-0.30 | 0.040 max | 0.035 max | 0.30 max | 0.40 max | 0.12 max |

| LF3 | 0.20 max | 0.9 max | 0.20-0.35 | 0.040 max | 0.035 max | 0.30 max | 3.3-3.7 | 0.12 max |

| LF5 | 0.30 max | 0.6-1.35 | 0.20-0.35 | 0.040 max | 0.035 max | 0.30 max | 1.0-2.0 | 0.12 max |

| LF6 | 0.22 max | 1.15-1.50 | 0.15-0.30 | 0.025 max | 0.025 max | 0.30 max | 0.40 max | 0.12 max |

| LF9 | 0.20 max | 0.40-1.06 | … | 0.040 max | 0.035 max | 0.30 max | 1.6-2.24 | 0.12 max |

| LF787 | 0.07 max | 0.40-0.70 | 0.4 max | 0.025 max | 0.025 max | 0.60-0.90 | 0.7-1.0 | 0.15-0.25 |

ASTM A350 LF3 Flanges mechanical performance parameters

| Grade | Tensile strength [MPa] | Yield strength, min,≥[MPa] | Elongation ≥% | Reduction of area, min,≥% |

| LF1 and LF5 Class 1 | 415-585 | 205 | 25 | 38 |

| LF2 Classes 1 and 2 | 485-655 | 250 | 22 | 30 |

| LF3 Classes 1 and 2 LF5 Class 2 | 485-655 | 260 | 22 | 35 |

| LF6 Class 1 | 455-630 | 360 | 22 | 40 |

| LF6 Classes 2 and 3 | 515-690 | 415 | 20 | 40 |

| LF9 | 435-605 | 315 | 25 | 38 |

| LF787 Class 2 | 450-585 | 380 | 20 | 45 |

| LF787 Class 3 | 515-655 | 450 | 20 | 45 |

ASTM A350 LF3 Flanges Tensile Properties Testing

ASTM A350 LF3 Flanges Impact Test Temperature |

||||||||||

| Grade | LF1 | LF2 Class 1 | LF2 Class 2 | LF3 Classes 1 and 2 | LF5 Classes 1 and 2 | LF6 Classes 1 and 2 | LF6 Class 3 | LF9 | LF787 Class 2 | LF787 Class 3 |

| Test Temperature [°C] | -29 | -46 | -18 | -101 | -59 | -51 | -18 | -73 | -59 | -73 |

| Carbon Steel A350 LF2 Socket Weld Flange Maximum Supplemental Test Temperatures | ||||||||||

| Grade | LF1 | LF2 Class 1 | LF3 Classes 1 and 2 | LF5 Classes 1 and 2 | LF6 Classes 1 and 2 | LF9 | LF787 Class 2 | LF787 Class 3 | LF2 Class 2 | LF6 Class 3 |

| Test Temperature [°C] | -23 | -37 | -87 | -51 | -40 | -62 | -51 | -62 | -12 | -12 |

2. Manufacturing and processing: The company uses advanced CNC machine tools, cutting machines, and other equipment for parts processing. These devices have the characteristics of high precision, high efficiency, and stability, which can ensure the accuracy and quality of the final product.

3. Welding assembly: The company uses automated welding equipment to weld components. These devices have the characteristics of high efficiency, energy conservation, and environmental protection, which can reduce energy consumption and environmental pollution, while also ensuring welding quality and speed. For flanges with strict requirements, the company will also use techniques such as ultrasonic testing to detect welds, ensuring the quality and performance of the product.

4. sandblasting and painting: The company uses advanced sandblasting and painting processes to treat products. These processes can remove surface oxides and rust, ensuring the appearance and quality of the final product.

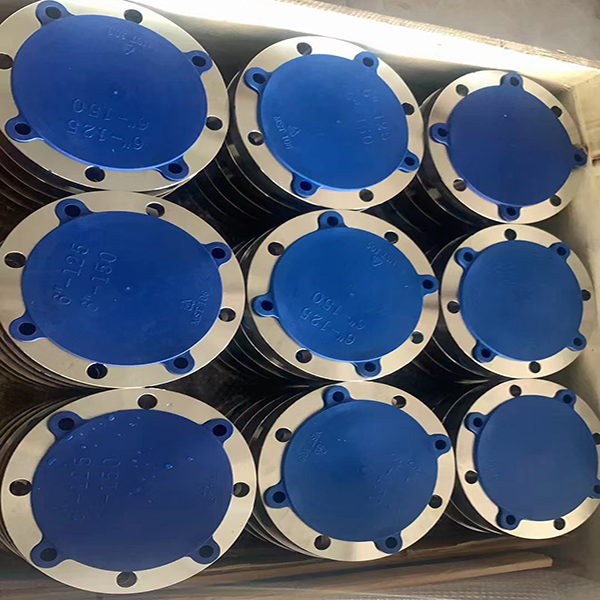

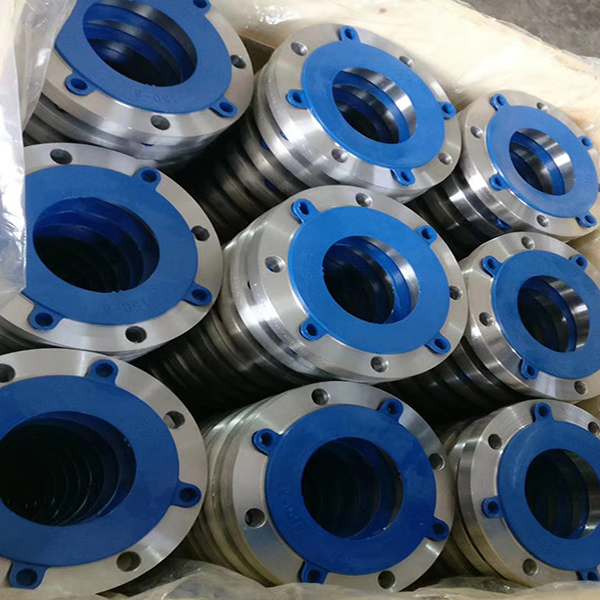

5. Packaging outbound: The products of Enfei Pipeline must undergo strict quality inspection and packaging before outbound. The surface of the product must be free of defects such as scratches and oxides, and packaged in a moisture-proof and rust proof manner.

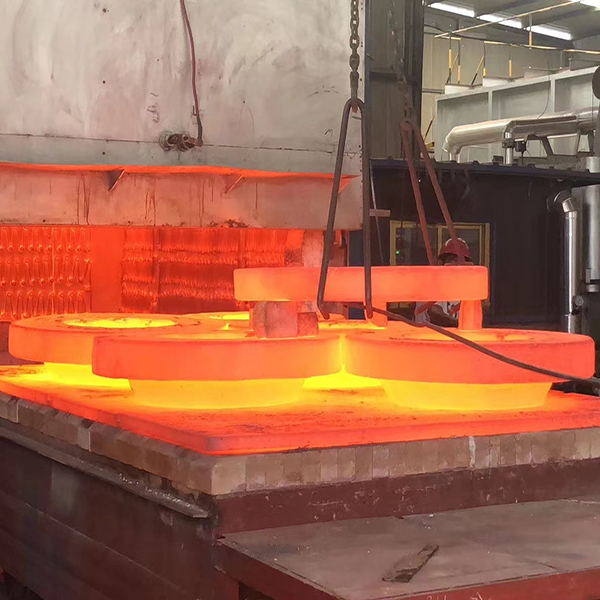

Heat treatment of ASTM A350 LF3 Flanges

3、 Advantages of ASTM A350 LF3 Flanges

The ASTM A350 LF3 Flanges produced by Enfei Pipeline has the following advantages:

1. Material Selection: High quality A350 LF3 steel is used as the raw material to ensure the performance and quality of the product. This type of steel has good corrosion resistance, oxidation resistance, and mechanical properties, and can still maintain good toughness and strength at temperatures below -45 ℃.

2. Manufacturing accuracy: ENFI pipeline uses advanced CNC machine tools and cutting machines for parts processing, which can ensure that the product has high accuracy and quality. Each part needs to go through multiple processes for manufacturing, and each processing process is strictly controlled to ensure the accuracy and quality of the final product.

3. Welding quality: Automatic welding equipment is used to weld components, and machine control is used to ensure the speed and quality of welding. For flanges with strict requirements, the company will also use techniques such as ultrasonic testing to detect welds, ensuring the quality and performance of the product.

4. Surface treatment: The product is treated using sandblasting and painting processes to ensure its appearance and quality. During the surface treatment process, the ENFI pipeline will remove oxides and rust on the surface, making the product surface smoother and achieving better anti-corrosion effects.

5. Cost advantage: ENFI pipeline adopts modern, automated, and intelligent manufacturing processes, improving production efficiency and reducing production costs. In addition, the company also adopts methods such as mass production and supply chain management to reduce costs, directly reflecting cost discounts on product prices, allowing customers to enjoy more favorable prices.

4、 Advantages and Services of Enfei Pipeline

Enfei Pipeline is a professional enterprise engaged in the manufacturing of various pipeline accessories, with rich experience and technology in the production and sales of ASTM A350 LF3 Flanges. The company has a professional technical team and after-sales service personnel, which can provide customers with comprehensive technical support, parts customization, and after-sales service. In addition, the company also has a comprehensive quality management system to ensure that the quality of each production process is controllable and measurable, and can provide relevant quality certificates and testing reports.

Enfei Pipeline can provide the following high-quality services:

1. Customized services: Provide customers with personalized product customization services based on their needs and requirements.

2. Delivery service: The company has a comprehensive production planning system and supply chain management system, which can directly reflect the production and supply situation, ensuring that customers receive timely delivery.

3. After sales service: The company provides lifelong free maintenance and provides after-sales services such as technical consultation, guidance, and training to ensure that customers can use the product with confidence.

4. Full process tracking: The company can achieve full process tracking and information feedback of orders through an integrated order management tracking system, allowing customers to better understand the progress and situation of orders.

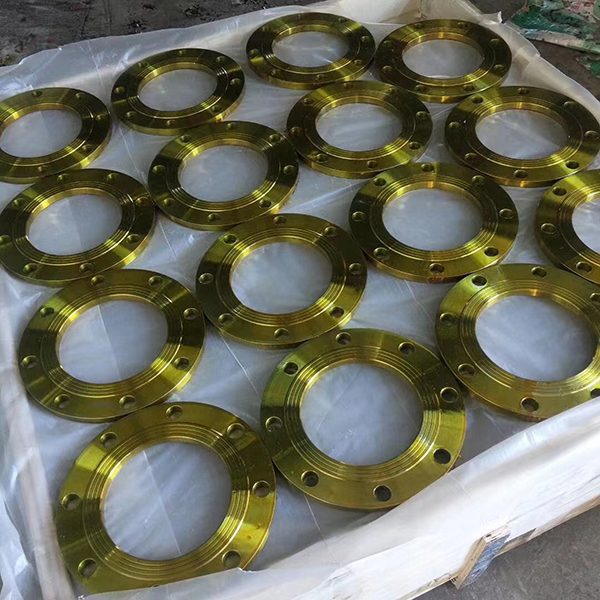

ASTM A350 LF3 Flanges packaging and delivery

5、 Conclusion

Enfei Pipeline Equipment Cangzhou Co., Ltd. is a professional enterprise engaged in the manufacturing of various pipeline accessories, with rich experience and technology in the production and sales of ASTM A350 LF3 Flanges. The company adopts modern, automated, and intelligent manufacturing processes to ensure product performance and quality, while also providing customers with personalized customized services and various after-sales services. Enfei Pipeline will continue to pursue excellence, progress and development, in order to better serve customers and promote the development of the industry.