Cangzhou Enfei Pipe Equipment Co., Ltd. is a professional enterprise engaged in the production and manufacturing of ASTM A350 LF6 Flanges. It has outstanding advantages among similar domestic enterprises and a high market share. Since its establishment, the company has always adhered to the business philosophy of “survival with quality, development with reputation”, and has won the trust and support of our customers with high-quality products and professional services.

1、 Company Overview

ENFI Pipeline Equipment Cangzhou Co., Ltd., founded in 2019, is located in Wuliyao Industrial Zone, Yanshan County, Cangzhou City, Hebei Province. It has modern plants and perfect equipment, first-class production technology and strict quality management system. The company has a group of skilled and experienced R&D personnel and technical workers, dedicated to the research and production of high-quality flange products.

2、 Product Introduction

ASTM A350 LF6 Flanges is a high-strength and high pressure pipeline connection accessory widely used in industries such as petrochemical, chemical, power, boiler, shipbuilding, papermaking, etc. The ASTM A350 LF6 Flanges produced by Enfei Pipeline Equipment Cangzhou Co., Ltd. has the following advantages:

Excellent material: Made of high-quality A350 LF6 material, it has high strength, toughness, corrosion resistance, and wear resistance;

Chemical composition of ASTM A350 LF6 Flanges

| Grade | C% | Mn% | Si% | S% | P% | Cr% | Ni% | Mo% |

| LF1 | 0.30 max | 0.6-1.35 | 0.15-0.30 | 0.040 max | 0.035 max | 0.30 max | 0.40 max | 0.12 max |

| LF2 | 0.30 max | 0.6-1.35 | 0.15-0.30 | 0.040 max | 0.035 max | 0.30 max | 0.40 max | 0.12 max |

| LF3 | 0.20 max | 0.9 max | 0.20-0.35 | 0.040 max | 0.035 max | 0.30 max | 3.3-3.7 | 0.12 max |

| LF5 | 0.30 max | 0.6-1.35 | 0.20-0.35 | 0.040 max | 0.035 max | 0.30 max | 1.0-2.0 | 0.12 max |

| LF6 | 0.22 max | 1.15-1.50 | 0.15-0.30 | 0.025 max | 0.025 max | 0.30 max | 0.40 max | 0.12 max |

| LF9 | 0.20 max | 0.40-1.06 | … | 0.040 max | 0.035 max | 0.30 max | 1.6-2.24 | 0.12 max |

| LF787 | 0.07 max | 0.40-0.70 | 0.4 max | 0.025 max | 0.025 max | 0.60-0.90 | 0.7-1.0 | 0.15-0.25 |

ASTM A350 LF6 Flanges mechanical performance parameters

| Grade | Tensile strength [MPa] | Yield strength, min,≥[MPa] | Elongation ≥% | Reduction of area, min,≥% |

| LF1 and LF5 Class 1 | 415-585 | 205 | 25 | 38 |

| LF2 Classes 1 and 2 | 485-655 | 250 | 22 | 30 |

| LF3 Classes 1 and 2 LF5 Class 2 | 485-655 | 260 | 22 | 35 |

| LF6 Class 1 | 455-630 | 360 | 22 | 40 |

| LF6 Classes 2 and 3 | 515-690 | 415 | 20 | 40 |

| LF9 | 435-605 | 315 | 25 | 38 |

| LF787 Class 2 | 450-585 | 380 | 20 | 45 |

| LF787 Class 3 | 515-655 | 450 | 20 | 45 |

ASTM A350 LF6 Flanges Tensile Properties Testing

ASTM A350 LF6 Flanges Impact Test Temperature |

||||||||||

| Grade | LF1 | LF2 Class 1 | LF2 Class 2 | LF3 Classes 1 and 2 | LF5 Classes 1 and 2 | LF6 Classes 1 and 2 | LF6 Class 3 | LF9 | LF787 Class 2 | LF787 Class 3 |

| Test Temperature [°C] | -29 | -46 | -18 | -101 | -59 | -51 | -18 | -73 | -59 | -73 |

| Carbon Steel A350 LF2 Socket Weld Flange Maximum Supplemental Test Temperatures | ||||||||||

| Grade | LF1 | LF2 Class 1 | LF3 Classes 1 and 2 | LF5 Classes 1 and 2 | LF6 Classes 1 and 2 | LF9 | LF787 Class 2 | LF787 Class 3 | LF2 Class 2 | LF6 Class 3 |

| Test Temperature [°C] | -23 | -37 | -87 | -51 | -40 | -62 | -51 | -62 | -12 | -12 |

2. Exquisite production process: Adopting international advanced production processes to ensure the accuracy and consistency of the products;

3. Excellent quality: All products have undergone multiple strict quality testing processes, ensuring stable and reliable product quality.

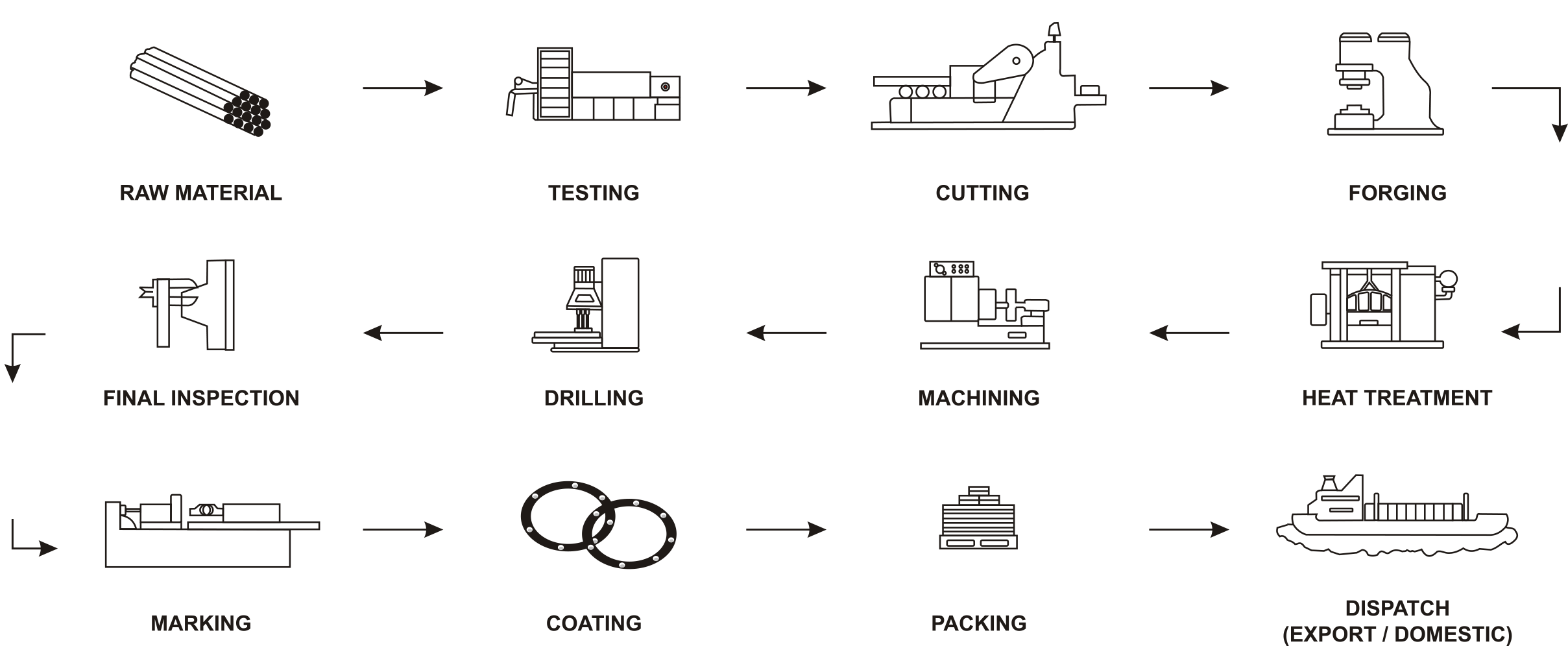

3、 Production process

The ASTM A350 LF6 Flanges production process of Enfei Pipeline Equipment Cangzhou Co., Ltd. includes the following steps:

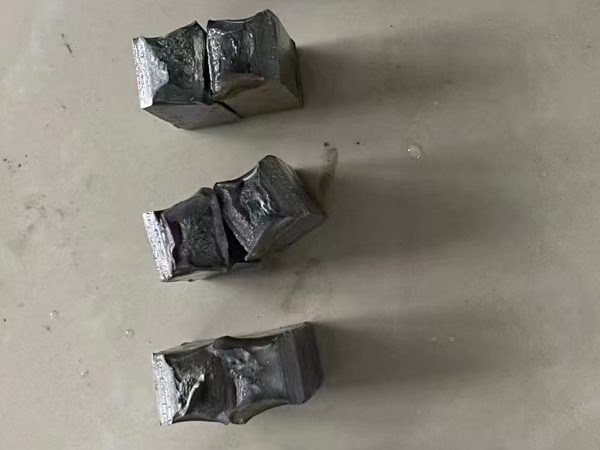

1. Raw material procurement: Select high-quality A350 LF6 materials to ensure excellent product quality.

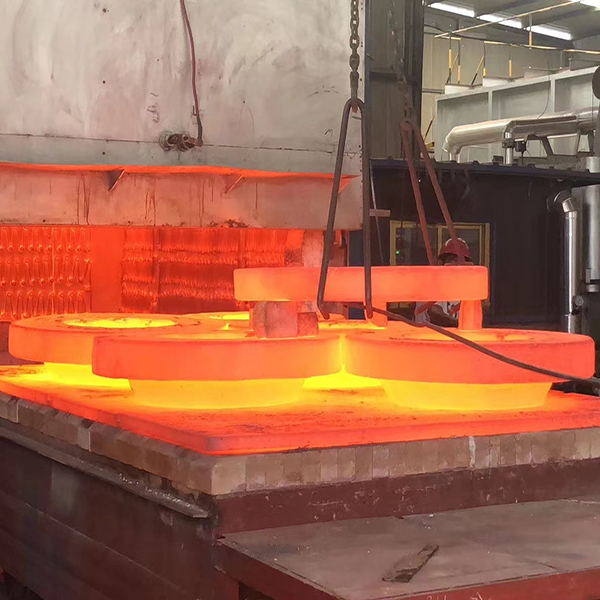

2. Forging processing: Advanced forging equipment and processes are used to ensure the shape and dimensional accuracy of the product.

3. Processing and testing: Use high-precision processing and testing equipment for processing and quality testing.

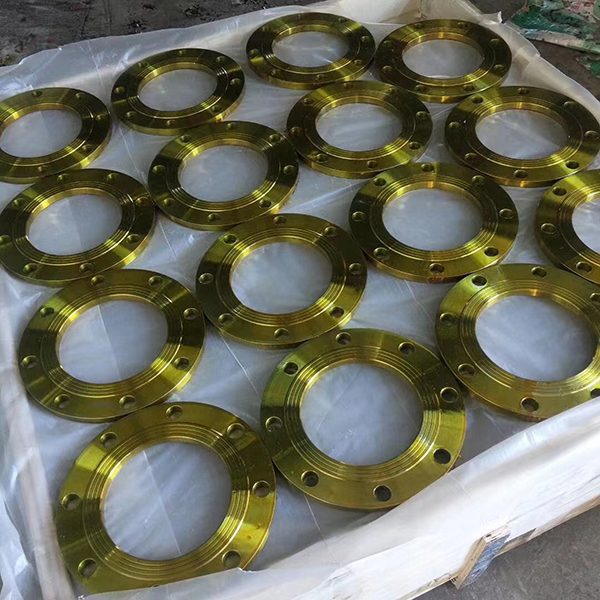

4. Surface treatment: According to customer requirements and different application scenarios, surface painting, heat treatment, and other treatments are carried out.

5. Packaging and transportation: Professional packaging materials and transportation methods are used to ensure the safe and reliable delivery of products to customers.

Heat treatment of ASTM A350 LF6 Flanges

4、 Quality management

Enfei Pipeline Equipment Cangzhou Co., Ltd. has always adhered to the principle of quality first in production and service. The company has established a comprehensive quality management system and has passed ISO9001 certification and PED certification. In order to ensure product quality and customer satisfaction, the company always prioritizes product quality in the development of the enterprise, conducts full process supervision and inspection, and strictly controls product quality.

5、 After sales guarantee

Enfei Pipeline Equipment Cangzhou Co., Ltd. has always adhered to the principle of “customer first” and provided customers with comprehensive after-sales support services. The company has professional personnel to coordinate before, during, and after sales, quickly respond to and solve customer needs, and provide more thoughtful service to customers.

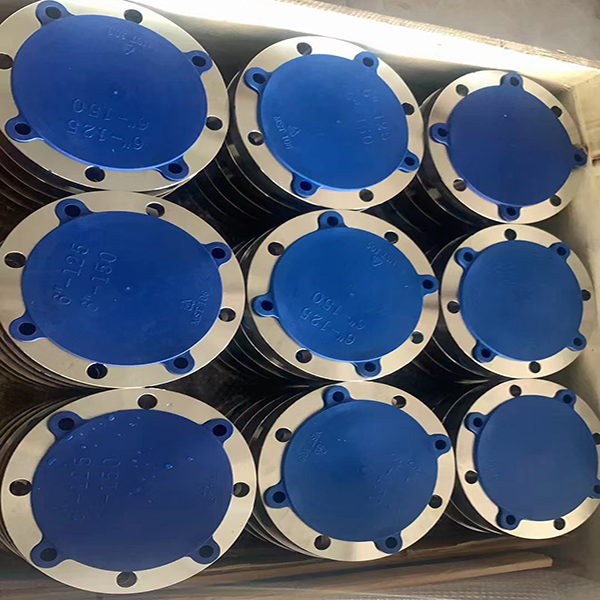

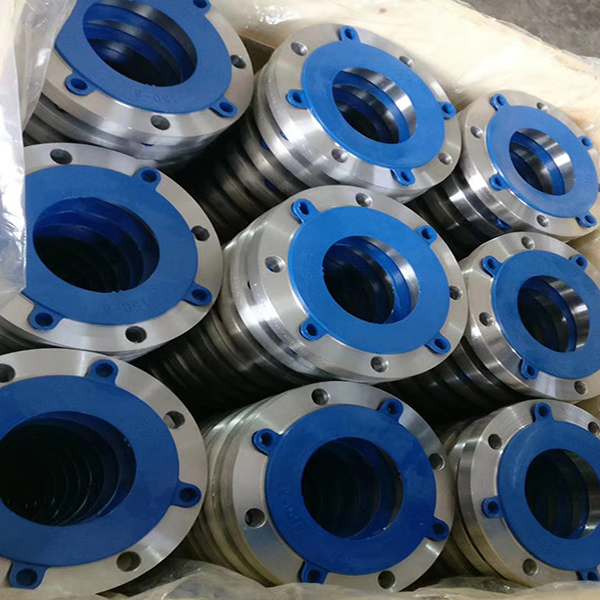

ASTM A350 LF6 Flanges packaging and delivery

6、 Summary

Enfei Pipeline Equipment Cangzhou Co., Ltd. is a professional enterprise engaged in the production and manufacturing of ASTM A350 LF6 Flanges. With rich production experience and a professional technical team, we are committed to providing customers with high-quality products and services. The company will continue to adhere to the business philosophy of “survival with quality, development with reputation”, wholeheartedly serve customers, and welcome customers to inquire and negotiate business.