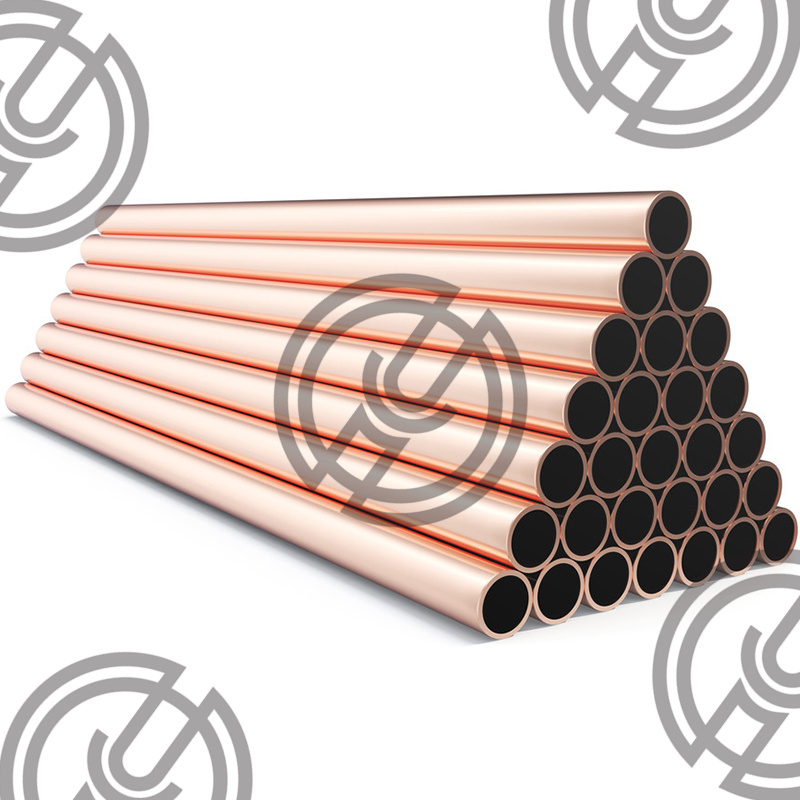

C70600 Pipes and Tubes (CUPRO NICKEL Pipes and Tubes), ASTM B466 UNS C70600 Pipe, CuNi 90/10 Pipe, ASME SB466 90/10 Copper Nickel Pipes and Tubes, ASTM B466 C70600 Copper Nickel Seamless Pipes, ASTM B466 CU-NI 90-10 Seamless Pipes, ASTM B466 C70600 Cupro Nickel Seamless Pipes and Tubes.

C70600 is a copper nickel alloy, also known as 90-10 copper nickel alloy. It is an alloy of copper and nickel, containing approximately 90% copper and 10% nickel, as well as a small portion of other alloying elements such as iron and manganese.

C70600 steel pipe has excellent corrosion resistance and mechanical properties, especially suitable for applications in seawater environments. The following are some characteristics and applications of C70600 Pipes:

1. Corrosion resistance: C70600 Pipes has excellent corrosion resistance, especially for seawater, salt water, and other corrosive media. Therefore, it is widely used in fields such as ocean engineering, ship construction, offshore platforms, and seawater treatment.

2. Mechanical properties: C70600 Pipes has high tensile strength and good impact toughness, and can maintain excellent mechanical properties even in seawater and low temperature conditions. Therefore, in the field of marine and offshore petrochemical industry, C70600 Pipes are commonly used for manufacturing equipment such as tanks, pipelines, heat exchangers, condensers, etc.

3. Welding performance: C70600 Pipes has good welding performance and is suitable for various welding methods, such as TIG welding, MIG welding, and resistance welding. Therefore, it has good weldability during the manufacturing and installation process.

It should be noted that although C70600 Pipes perform well in most cases, there are also some limitations, especially in high temperature and highly corrosive environments. For applications under special conditions, a comprehensive evaluation and selection should be conducted based on specific engineering and environmental requirements.

C70600 Pipes Specifications

C70600 Pipe Specifications : ASTM / ASME SB 111 / 466 / 7060X/ CuNi10Fe1.6Mn/ CN102

C70600 Pipe Standard : ASTM, ASME B36.19,DIN 86019, EEMUA 144,EEMUA 234,MIL-T-16420K

C70600 Pipe Size : 1/2″ TO 20′ IN,DN15 TO DN500

Outer Diameter : 15mm to 508mm

Wall Thickness : Between 1mm and 11 mm

Length : mainly 6meter or required Length

Schedule : sch10,sch40,sch80,std

C70600 Pipe Pressure Rating:

10bar, 14bar for DIN 86019

16bar,20bar for EEMUA 144,EEMUA 234

Class 200, Class 700 for MIL-T-16420K.

Types : Seamless less than 419mm ( included 419mm) / Seam Welded ( over 419mm )

End : Plain End, Beveled End, Treaded

Grades : Copper Nickel 90/10 (C70600 ), Cupro Nickel 70/30 (C71500), UNS C71640

ASTM B111 for UNS C70600 tubes

ASTM B171 for UNS C70600 plates

ASTM B466 for UNS C70600 pipes

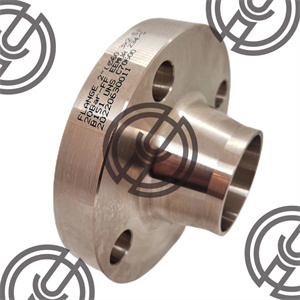

ASTM B151 for UNS C70600 bars, it can be forged to be C70600 flanges

Equivalent materials to UNS C70600 copper alloy are given in the table below.

| ASME SB111 | ASME SB171 | ASME SB359 | ASME SB466 | ASME SB467 |

| ASME SB395 | ASME SB543 | ASTM B111 | ASTM B151 | ASTM B122 |

| ASTM B171 | ASTM B359 | ASTM B395 | ASTM B432 | ASTM B466 |

| ASTM B469 | ASTM B543 | ASTM B608 | DIN 2.0872 | MIL C-15726 |

| MIL T-15005 | MIL T-16420 | MIL T-22214 | SAE J461 | SAE J463 |

c70600 chemical composition

| DIN 86019 2.1972 |

EEMUA 144 UNS 7060X |

BS 2871 CN 102 |

ASTM B466 C70600 |

JIS H 3300 C7060 |

MIL-T-16420K C70600 |

|

|---|---|---|---|---|---|---|

| Ni% | 9.0-11.0 | 10.0-11.0 | 10.0-11.0 | 9.0-11.0 | 9.0-11.0 | 9.0-11.0 |

| Fe% | 1.5-1.8 | 1.5-2.0 | 1.0-2.0 | 1.0-1.8 | 1.0-1.8 | 1.0-1.8 |

| Mn% | 0.5-1.0 | 0.5-1.0 | 0.5-1.0 | Max.1.0 | 0.2-1.0 | Max1.0 |

| C% | Max.0.05 | Max.0.05 | Max.0.05 | Max.0.05 | Max.0.05 | |

| Pb% | Max.0.03 | Max.0.01 | Max.0.01 | Max.0.02 | Max.0.05 | Max.0.02 |

| S% | Max.0.015 | Max.0.02 | Max.0.05 | Max.0.02 | Max.0.02 | |

| P% | Max.0.02 | Max.0.02 | Max.0.02 | Max.0.02 | ||

| Zn% | Max.0.15 | Max.0.20 | Max.0.50 | Max.0.50 | Max.0.05 | |

| Zr% | Max.0.03 | |||||

| Others | Max.0.30 | Max.0.30 | Max.0.30 | |||

| Cu% | Balance | Balance | Balance | Balance | Cu+Ni +Fe+Mn Min.99.5 |

Min.86.5 |

The following table shows the physical properties of UNS C70600 copper nickel alloys.

| Properties | Metric | Imperial |

|---|---|---|

| Density | 8.94 g/cm3 | 0.323 lb/in3 |

The Mechanical Properties of UNS C70600 copper nickel alloys are displayed in the following table.

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength, ultimate | 303-414 MPa | 43900-60000 psi |

| Tensile strength, yield (depending on temper) | 110-393 MPa | 16000-57000 psi |

| Elongation at break (in 254 mm) | 42.00% | 42.00% |

| Machinability (UNS C36000 (free-cutting brass) = 100%) | 20% | 20% |

| Shear modulus | 52.0 GPa | 7540 ksi |

| Poisson’s ratio | 0.34 | 0.34 |

| Elastic modulus | 140 GPa | 20300 ksi |

C70600 pipes has a wide range of applications and good prospects in marine engineering and ship construction. The following are its main applications and prospects in these fields:

1. Marine engineering applications: C70600 pipes have excellent corrosion resistance and mechanical properties in marine engineering, especially suitable for use in seawater environments. It is commonly used for manufacturing subsea pipelines, oil and gas extraction equipment, offshore platform structures, etc. Submarine pipelines are used to transport offshore oil and natural gas resources, and the C70600 pipeline can withstand the effects of seawater corrosion and high-pressure environments, ensuring the reliability and lifespan of the pipeline. In addition, C70600 pipes can also be used for ocean heat exchangers, condensers, and water supply and drainage systems.

2. Application in ship construction: C70600 pipes also have important applications in ship construction. Ships often face seawater corrosion and high humidity environments, so materials need to have good corrosion resistance. C70600 pipe can provide good corrosion resistance and can be used for manufacturing cooling systems, seawater treatment systems, fuel pipelines, etc. in ships. In addition, C70600 pipes can also be used for marine life-saving equipment, coastal protection engineering, etc.

3. Prospects: With the continuous increase in the development and utilization of marine resources, the demand for materials with excellent corrosion resistance in the fields of marine engineering and ship construction is also increasing. C70600 tube, as a copper nickel alloy tube with excellent corrosion resistance and mechanical properties, has broad application prospects. With the continuous development of technology and the expansion of applications, the application of C70600 pipes in marine engineering and ship construction will be further expanded and deepened.

In summary, C70600 pipes are widely used in marine engineering and ship construction, and have good prospects. Its corrosion resistance and mechanical properties make it an ideal choice for marine environments, providing reliable material support to ensure the safety and reliability of engineering and ships.