API 5L Grade B Carbon Steel SSAW Pipe – Technical Specifications

1. Overview

API 5L Grade B SSAW (Spiral Submerged Arc Welded) pipes are carbon steel pipes manufactured for oil, gas, and water transmission pipelines. They are produced by helical (spiral) welding and comply with the API 5L standard, ensuring suitability for high-pressure, long-distance transportation.

2. Key Features

| Parameter | Details |

|———————-|————|

| Standard | API 5L (PSL1 or PSL2) |

| Grade | B (Equivalent to ASTM A53/A106 Gr. B) |

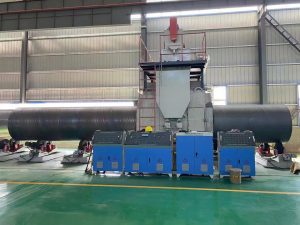

| Manufacturing | Spiral Submerged Arc Welding (SSAW) |

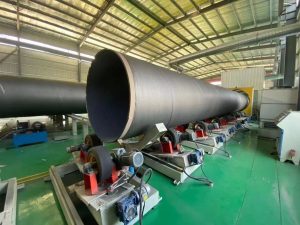

| Size Range | OD: 20″ – 100″ (508mm – 2540mm) |

| Wall Thickness | 6mm – 25mm (varies by diameter) |

| Pressure Rating | Suitable for medium to high-pressure pipelines |

3. Mechanical Properties

| Property | PSL1 (Standard) | PSL2 (Enhanced) |

|—————————-|———————|———————|

| Yield Strength (min) | 245 MPa (35,500 psi) | 290 MPa (42,100 psi) |

| Tensile Strength | 415-655 MPa | 415-655 MPa |

| Elongation (min) | ≥ 20% | ≥ 20% |

| Impact Test (Charpy V-Notch) | Not required (PSL1) | ≥ 27J @ 0°C (PSL2) |

4. Chemical Composition (%)

| Element | PSL1 (max) | PSL2 (max) |

|————-|—————-|—————-|

| Carbon (C) | 0.22 | 0.22 |

| Manganese (Mn) | 1.20 | 1.20 |

| Phosphorus (P) | 0.025 | 0.025 |

| Sulfur (S) | 0.015 | 0.015 |

| Silicon (Si) | 0.45 | 0.45 |

5. Manufacturing Process

1. Coil Preparation – Steel coils are unrolled and leveled.

2. Spiral Forming – The strip is helically bent into a pipe shape.

3. Submerged Arc Welding (SAW) – The seam is welded internally and externally.

4. Sizing & Straightening – The pipe is calibrated for dimensional accuracy.

5. Testing & Inspection – Hydrostatic, ultrasonic (UT), and visual checks.

6. Testing & Inspection

– Hydrostatic Test – Mandatory (test pressure per API 5L).

– Non-Destructive Testing (NDT) – Ultrasonic (UT) or Radiographic (RT) weld inspection.

– Mechanical Testing – Tensile, hardness, and bend tests.

– Dimensional Checks – OD, wall thickness, and straightness verification.

7. Applications

✔ Oil & Gas Transmission Pipelines

✔ Water Supply & Sewage Systems

✔ Structural Piling (in some cases)

✔ Industrial Process Piping

8. Advantages of SSAW Pipes

✅ Large Diameter Availability (up to 100″ / 2540mm)

✅ Cost-Effective for Long-Distance Pipelines

✅ High Strength & Durability

✅ Good Weldability & Formability

9. Limitations

⚠ Not suitable for high-pressure gas lines (PSL1 lacks impact testing)

⚠ Thicker welds compared to LSAW pipes

⚠ Requires proper anti-corrosion coating (FBE, 3LPE, etc.)

10. Comparison with Other Pipe Types

| Feature | SSAW (API 5L Gr. B) | LSAW (API 5L Gr. B) | ERW (API 5L Gr. B) |

|——————–|————————–|————————–|————————|

| Manufacturing | Spiral welding | Longitudinal welding | Electric resistance welding |

| Max Diameter | 100″ (2540mm) | 60″ (1524mm) | 24″ (610mm) |

| Weld Quality | Good | Excellent | Good |

| Cost | Moderate | High | Low |

11. Ordering Information

When ordering, specify:

– API 5L Grade B (PSL1 or PSL2)

– Diameter & Wall Thickness

– Length (Single/Double Random or Fixed)

– Coating Requirements (e.g., 3LPE, FBE, Galvanized)

– Supplementary Tests (Impact, PMI, etc.)

API 5L Grade B SSAW pipes are cost-effective, large-diameter pipes ideal for oil, water, and gas transmission. They offer good strength and weldability but require proper corrosion protection for long-term use. For high-pressure gas lines, PSL2 with impact testing is recommended.