NORSOK M-650 Certification requirements for Duplex Steel S31803 Pipe Fittings.

1、 Project Overview

NORSOK M-650 is a Norwegian Petroleum engineering standard. This standard was developed by the Norwegian Ministry of Industry and Energy, which specifies the materials, equipment, tools, manufacturing and installation requirements used in the oil and gas industry to ensure safe, reliable, and efficient extraction, production, and processing of oil and gas. UnderNORSOK M-650 Certification, there are specific requirements for the use of various materials, including materials such as duplex stainless steel.

S31803 duplex stainless steel is a material with both ferrite and austenite structures. Its material performance is stable, and it has good corrosion resistance, strength, and welding performance. It is widely used in fields such as petrochemical, marine engineering, automobiles, medical equipment, etc.

2、 Introduction to Duplex Steel S31803 Pipe Fittings

S31803 duplex stainless steel is a type of steel with high corrosion and wear resistance, good weldability, superior strength and toughness. This type of steel has both ferrite and austenite, and has advantages such as high stress corrosion resistance, heat resistance, and fatigue resistance.

Duplex Steel S31803 Pipe Fittings Chemical Composition

| UNS | Abbreviation | C% | Mn% | Si% | Cr% | Ni% | Mo% | S% | P% | N% |

| S31803 | 2205 | 0.03 max | 2 max | 1 max | 21.0-23.0 | 4.5-6.5 | 2.5-3.5 | 0.015 max | 0.035 max | 0.1-0.22 |

| S32205 | 0.03 max | 2 max | 1 max | 21.0-23.0 | 4.5-6.5 | 2.5-3.5 | 0.015 max | 0.035 max | 0.1-0.22 | |

| S32750 | 2507 | 0.03 max | 2 max | 1 max | 24.0-26.0 | 6.0-8.0 | 3.0-4.5 | 0.015 max | 0.035 max | 0.24-0.35 |

| S32760 | Zeron 100 | 0.03 max | 1 max | 1 max | 24.0-26.0 | 6.0-8.0 | 3.0-4.0 | 0.01max | 0.03max | 0.03max |

| S31254 | 254SMO | 0.02max | 0.03max | 0.7max | 19.5-20.5 | 17.5-18.5 | 6-7 | 0.01max | 0.03max | 0.18-0.25 |

Duplex Steel S31803 Pipe Fittings have the following advantages:

1. It has good corrosion resistance and can operate safely in marine environments, hydrochloric acid, sulfuric acid, and other media.

2. It has excellent strength and toughness, and can withstand high temperature, high pressure, and impact loads, greatly improving the safety and reliability of pipeline systems.

3. It has good processing and welding performance, making it convenient for processing and assembly during the production process.

4. It has good environmental performance and can greatly reduce production costs and environmental pollution.

Duplex Steel S31803 Pipe Fittings Tensile Properties at Room Temperature

| UNS | Abbreviation | Tensile strength [MPa] | Yield strength, min,≥[MPa] | Reduction of area, min,≥% | Dichte |

| S31803 | 2205 | 640-920 | 450 | 22 | 7.8 |

| S32205 | 640-880 | 450 | 22 | 7.8 | |

| S32750 | 2507 | 580-800 | 550 | 20 | 7.81 |

| S32760 | Zeron 100 | 750-895 | 550 | 25 | 7.81 |

| S31254 | 254SMO | 650-850 | 300 | 35 | 8 |

3、 NORSOK M-650 Certification requirements for Duplex Steel S31803 Pipe Fittings

NORSOK M-650 certification requires materials, equipment, tools, manufacturing, and installation processes that comply with relevant standards to maintain safety, stability, reliability, and efficiency in a consistent manner during use.

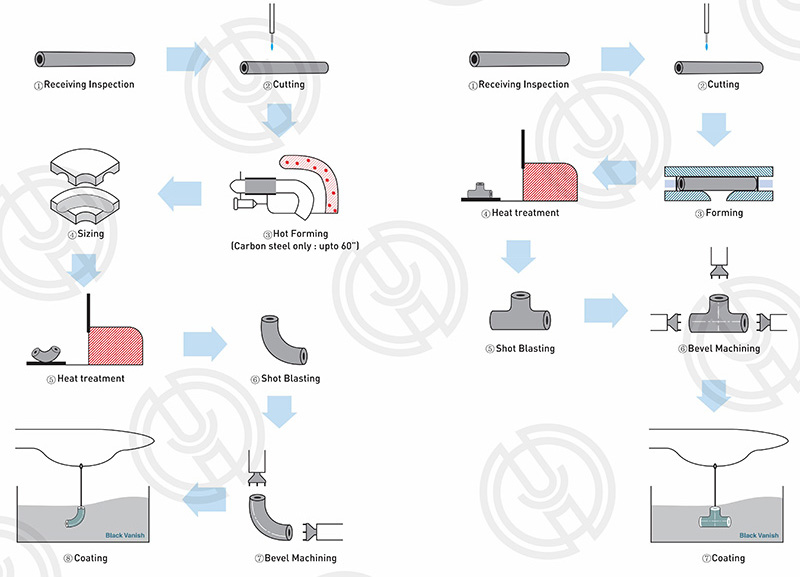

S31803 Heat treatment of duplex stainless steel pipe fittings S31803 Solution heat treatment of duplex stainless steel pipe fittings

For Duplex Steel S31803 Pipe Fittings, NORSOK M-650 Certification has the following requirements:

1. Chemical composition: The chemical composition of the pipe fittings must comply with the requirements of ASTM A815 S31803 standard and NACE MR0175 to ensure that there is no contamination of the medium.

2. Material performance: The material performance of pipe fittings must comply with the requirements of ASTM A815 S31803 standard and NACE MR0175, ensuring that corrosion resistance, strength, and toughness meet the usage requirements.

Duplex Steel S31803 Pipe Fittings inspection

3. Heat treatment: The heat treatment of pipe fittings must comply with the requirements of ASTM A815 S31803 standard and NACE MR0175 to ensure uniform material structure and stable performance.

4. Coating: The coating of the pipe fittings must comply with the requirements of NORSOK M-501 to improve the corrosion resistance of the pipe fittings.

5. Inspection: The manufacturing process of pipe fittings must comply with the quality control requirements of NORSOK M-650 to ensure that the quality of the pipe fittings can meet the usage requirements.

6. Identification: The pipe fittings must be correctly identified in accordance with the requirements of NORSOK M-630, and the identification information must be clear and clear.

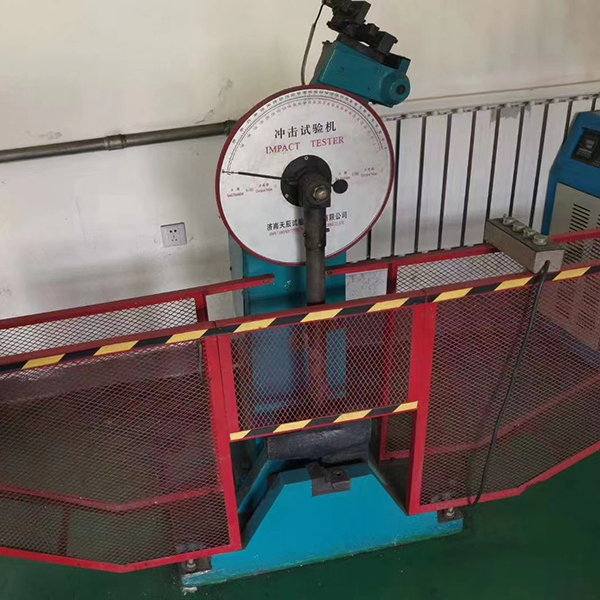

Mechanical properties and welding test of Duplex Steel S31803 Pipe Fittings

S31803 Welding Procedure Evaluation of Duplex Stainless Steel Pipe Fitting S31803 Impact Energy Experiment of Duplex Stainless Steel Pipe Fitting S31803 Inspection of Duplex Stainless Steel Pipe Fitting

4、 Application of S31803 duplex stainless steel pipe fittings in NORSOK M-650 certification

S31803 duplex stainless steel pipe fittings have excellent corrosion resistance, strength, and toughness, and have been widely used in fields such as petrochemical, marine engineering, automobiles, medical equipment, etc. They also have important applications in NORSOK M-650 Certification.

Heat treatment of Duplex Steel S31803 Pipe Fittings

In the field of petroleum and natural gas, S31803 duplex stainless steel fittings are widely used in subsea oil and gas pipelines, offshore drilling platforms, chimney systems, and transportation pipeline systems for petroleum refining, hydrogenation, catalytic conversion, and other processes. Through NORSOK M-650 Certification, there are clear requirements and standards for the use of S31803 duplex stainless steel pipe fittings, which can ensure their safe and stable operation in the field of petroleum and natural gas.

Duplex Steel S31803 Pipe Fittings packaging and delivery

5、 Conclusion

NORSOK M-650 Certification requires materials, equipment, tools, manufacturing, and installation processes that meet standards to maintain safety, stability, reliability, and efficiency in a consistent manner during use. For Duplex Steel S31803 Pipe Fittings, NORSOK M-650 Certification has strict requirements and standards to ensure its safe and stable operation in the oil and gas related fields. Duplex Steel S31803 Pipe Fittings have advantages such as good corrosion resistance, strength, and toughness, and have broad application prospects in fields such as petrochemical and marine engineering in the future. Translate full text in English