GET IN TOUCH WITH NFI STEEL

Stainless Steel Flanges A182 F304L F316L Welding Neck Flange

Stainless Steel Flanges A182 F304L F316L F321 has good corrosion resistance and is widely used in shipbuilding, petroleum, chemical industry, water treatment, medicine and other fields.

Stainless Steel Flanges ASTM A182 F304L F316L F321 F310 F347 F316Ti F904L F310MoLN

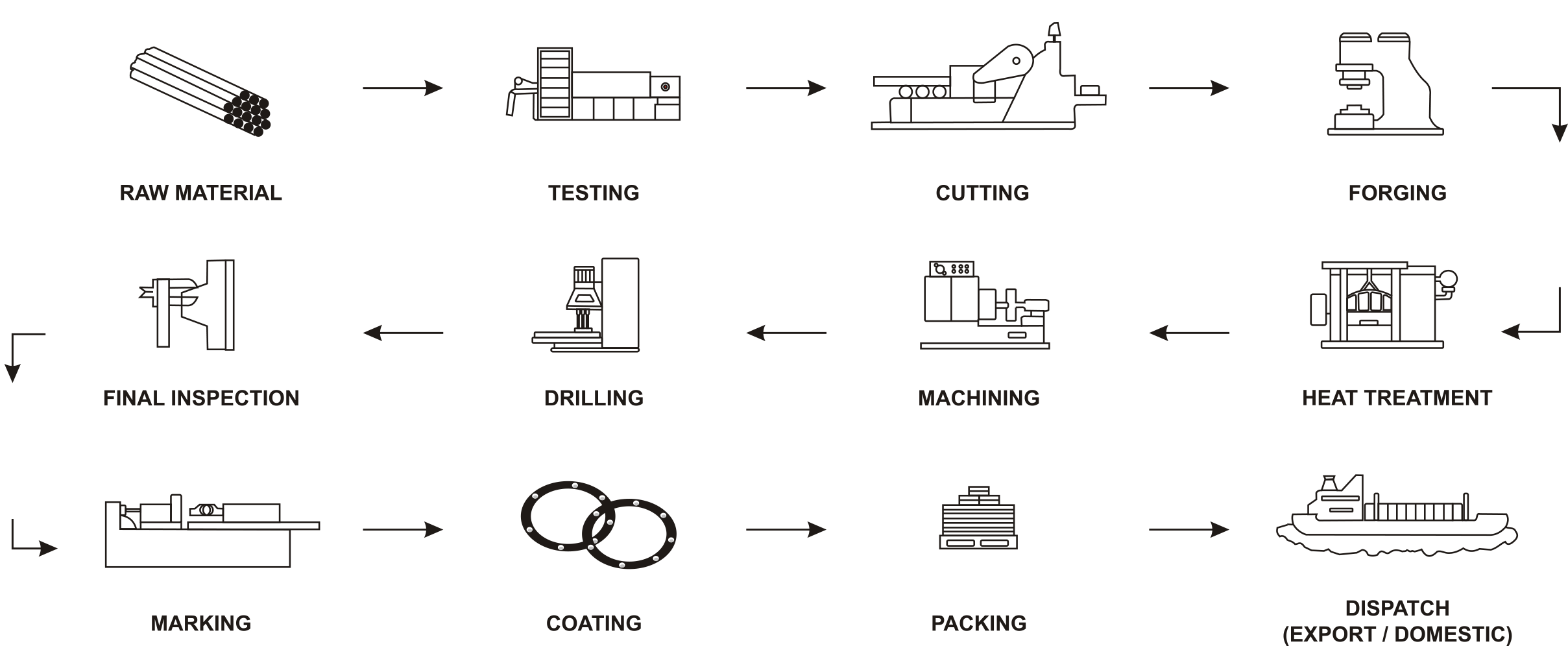

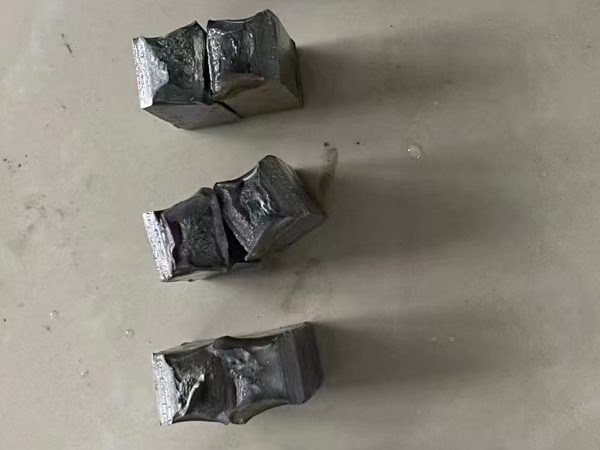

Cangzhou Enfei Pipe Equipment Co., Ltd. is an excellent Stainless Steel Flanges ASTM A182 F304L F316L F321 manufacturer in China,The Stainless Steel Flanges ASTM A182 F304L F316L F321 is a product formed by high-temperature and high-pressure forging of the raw material metal round bar or steel plate. Therefore, the Stainless Steel Flanges ASTM A182 F304L F316L F321 has high requirements for raw materials.

Whether the raw materials are high-quality determines the quality of the Stainless Steel Flanges ASTM A182 F304L F316L F321 products. Next, the Stainless Steel Flanges ASTM A182 F304L F316L F321 performance is determined by the heat treatment process. The heat treatment temperature is generally between 700 and 1300 degrees Celsius. The heat treatment process determines the low-temperature impact resistance, high-temperature resistance, corrosion resistance Standard parameters such as welding performance and hardness.

As an excellent Stainless Steel Flanges ASTM A182 F304L F316L F321 manufacturer, Cangzhou Enfei Pipe Equipment Co., Ltd. selects raw materials produced by the best factories in China, including Yongxing special steel, AVIC Shangda, Huaxin Lihua, qingtuo group, Laiwu Iron and steel, Valin Iron and steel, Taiyuan Iron and steel, Shanghai Baosteel, Baosteel and other China’s best steel groups. The above raw material manufacturers have passed ABS and DNV GL, BV, LR, CCS, NKclass, KR, RINA and RS classification societies can issue EN10204 3.2 and EN10204 3.1 material list certificates.

Cangzhou Enfei Pipe Equipment Co., Ltd. focuses on serving global customers. Manufacturing standards include: ASME/ANSI B16.9, ASME/ANSI B16.47, ASME /ANSI B16.48, MSS SP44, ASA, API-605, AWWA, custom drawings DIN2527-DIN2673, EEMUA145 146 234, BS4504, BS1560, BS10, HG/T20592 HG/T20615, GB /T9115-GB/T9119, JIS B2220, JPI-7S-15, etc.

Stainless Steel Flanges products produced by Cangzhou Enfei Pipe Equipment Co., Ltd. have a variety of materials to choose from, including:ASTM A182 F11 CL1 F11 Cl2 F11 CL3 F12 CL1 F12 Cl2 F304 F304H F30L F317 F321 F347 F51 F53 F55 F60. Stainless Steel Flanges ASTM A182 F304L F316L F321 product pressure 75LB 150LB 300LB 400LB 600LB 900LB 1500LB 2500LB DIN Standard PN-2.5,6,10,16,25,40,50,64,110,150,250,320,400, and product specification 1/8-72 inch to meet customers’ various choices.

Due to the high standard, good material and many specifications of Stainless Steel Flanges ASTM A182 F304L F316L F321 provided by our company, we are able to undertake many small, medium and large projects, coupled with our service attitude of resolutely considering for customers, which also makes our customers have a high rate of return.

The contracts signed and delivered come from Europe, Africa, Asia, South America, North America, etc., with a wide range of customer coverage, and have won the unanimous praise of customers. Our company also keeps refining its products to meet the new issues raised in the new era while the rapid development of the times.

Industrial Steel Flanges Test Certificates: Cangzhou Enfei Pipe Equipment Co., Ltd. offer its Products with Third Party Inspection also.The Inspection Agency can be nominated by clients or Dynamic Forge & Fittings can be arrange the TPI by World reputed Agencies like Bureau Veritas, ABS, NKClass,SGS and many other.

Stainless Steel Flanges A182 F304L F316L F321 Specification

| Size | 1/2〞(DN15)to 60〞(DN1500) | |||||

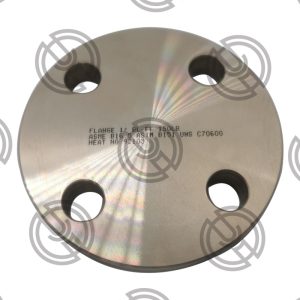

| Products | Stainless Steel F304L Slip-On Flanges,Stainless Steel F316L Weld Neck Flanges,Stainless Steel F321 Blind Flanges,Stainless Steel F347 Lap Joint Flanges,Stainless Steel F310 Ring Type Joint Flanges,Stainless Steel F310MoLN Threaded Flanges, Stainless Steel F316TI Socket Weld Flanges

Stainless Steel F904L Reducing Flanges,Stainless Steel S30403 Plate Flanges, Stainless Steel S31603 Forged Flanges,Stainless Steel S32100 Square Flanges,Stainless Steel S34700 Spectacle Blind Flanges |

|||||

| Class | 150LBS,300LBS,400LBS,600LBS,900LBS,1500LBS,2500LBS. DIN Standard PN-2.5,6,10,16,25,40,50,64,110,150,250,320,400. | |||||

| Flange Face Type | Amerrican Series:Flat face(FF),Raised Face(RF),Tongue(T),Groove(G),Female(F),Male(M),Ring Joints Face(RJ) | |||||

| Surface Treatment | Antirust Paint,Oil Black Paint,Yellow Transparent,Zinc Plated,Cold and Hot Dip Galvanized | |||||

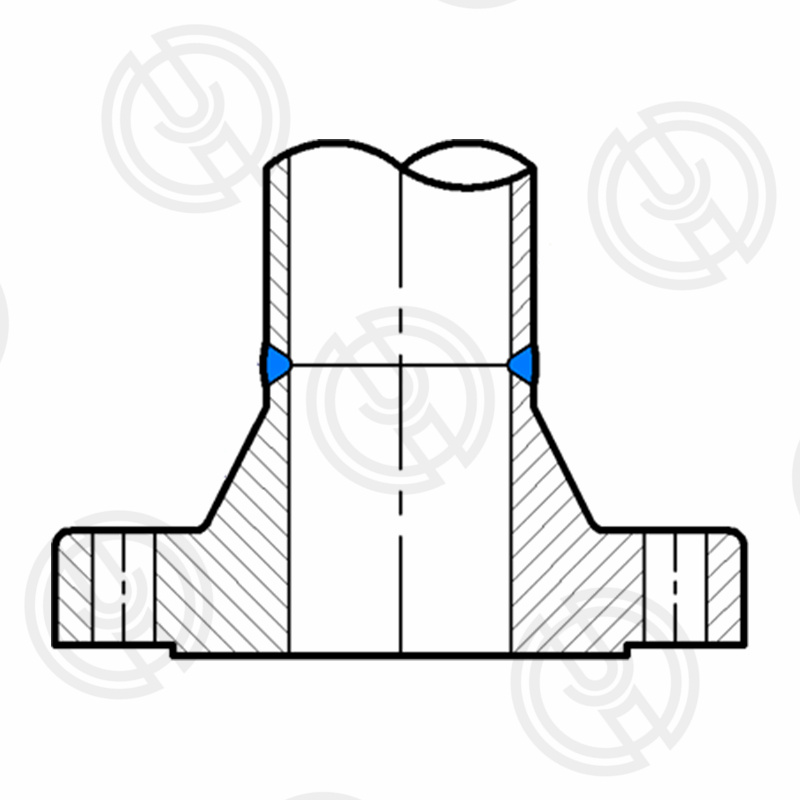

| Manufacturing process | Cutting,Heat treatment,Die Forging/Free Forging,CNC Machining | |||||

| Manufacturing Standards | ANSI/ASME B16.5 Flanges,ANSI/ASME B16.47 Flanges,ANSI/ASME B16.36 Flanges,ANSI/ASME B16.48 Flanges ,MSS SP44 Flanges,ASA,API-605 Flanges

AWWA Flanges,Custom Drawings Flanges ,EEMUA145 146 234 Flanges,BS 10 Flanges,DIN Flanges,EN 1092-1 Flanges,BS 4504 Flanges,JIS Standard Flanges |

|||||

| Stainless Steel | ASTM A182 F304L,F316L,F321,F310,F310MoLN, F316H,F316LN, F316TI, F317,F317H,F347,F347H,F51,F53,F55,F60,F904L,F91 | |||||

Stainless Steel Flanges ASTM A182 F304L F316L F321 Chemical Composition

| Grade | UNS | C% | Mn% | Si% | S% | P% | Cr% | Ni% | Mo% |

| F304L | S30403 | 0.30 max | 2.00 max | 1.00 max | 0.03 max | 0.045 max | 18.00-20.00 | 8.00-13.00 | |

| F316L | S31603 | 0.30 max | 2.00 max | 1.00 max | 0.03 max | 0.045 max | 16.00-18.00 | 10.00-15.00 | 2.00-3.00 |

| F321 | S32100 | 0.08 max | 2.00 max | 1.00 max | 0.03 max | 0.045 max | 17.00-19.00 | 9.00-12.00 | |

| F310 | S31000 | 0.25 max | 2.00 max | 1.00 max | 0.03 max | 0.045 max | 24.00-26.00 | 19.00-22.00 | |

| F347 | S34700 | 0.08 max | 2.00 max | 1.00 max | 0.03 max | 0.045 max | 17.00-20.00 | 9.00-13.00 | |

| F316Ti | S31653 | 0.08 max | 2.00 max | 1.00 max | 0.03 max | 0.045 max | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 |

| F904L | N08904 | 0.02 max | 2.00 max | 1.00 max | 0.03 max | 0.04 max | 19.00-23.00 | 23.00-28.00 | 4.00-5.00 |

| F310MoLN | S31050 | 0.03 max | 2.00 max | 0.4 max | 0.015 max | 0.03 max | 24.00-26.00 | 21.00-22.00 | 2.00-3.00 |

Stainless Steel Flanges A182 F304L F316L F321 Tensile Properties Testing

Stainless Steel Flanges ASTM A182 F304L F316L F321 Tensile Properties at Room Temperature

| Grade | Tensile strength ≥[MPa] | Yield strength, min,≥[MPa] | Elongation ≥% | Reduction of area, min,≥% |

| F304L Welding Neck Flange | 485 | 170 | 30 | 50 |

| F316L Slip On Flange | 485 | 170 | 30 | 50 |

| F321 Socket Weld Flange | 515 | 205 | 30 | 50 |

| F310 Blind Flanges | 515 | 205 | 30 | 50 |

| F347 Lap Joint Flange | 515 | 205 | 30 | 50 |

| F316Ti Long Neck Weld Flanges | 515 | 205 | 30 | 40 |

| F904L Spectacle Blind Flanges | 490 | 215 | 35 | |

| F310MoLN Orifice Flanges | 540 | 255 | 25 | 50 |

Stainless Steel Flanges ASTM A182 F304L F316L F321 Heat Treating Requirements

| Grade | Heat Treat Type | Solutioning Temperature ℃ | Cooling Mode | Quenching Cool Below ℃ |

| F304L Slip On Flange | Solution treat and quench | 1040 | Liquid | 260 |

| F316L Welding Neck Flange | Solution treat and quench | 1040 | Liquid | 260 |

| F321 Socket Weld Flange | Solution treat and quench | 1040 | Liquid | 260 |

| F310 Jacket Flanges | Solution treat and quench | 1040 | Liquid | 260 |

| F347 Threaded Flange | Solution treat and quench | 1040 | Liquid | 260 |

| F316Ti API Flanges | Solution treat and quench | 1040 | Liquid | 260 |

| F904L Blind Flange | Solution treat and quench | 1050-1100 | Liquid | 260 |

| F310MoLN Plate Flanges | Solution treat and quench | 1050-1100 | Liquid | 260 |

Related products

-

FLANGE

Copper Nickel Flanges | C70600 Flanges | C71500 Flanges Manufacturer

Read moreRated 0 out of 5 -

FLANGE

ASTM A350 LF2 Flanges Socket Weld Flange

Rated 0 out of 5$100.00Original price was: $100.00.$9.00Current price is: $9.00. Add to cart